feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

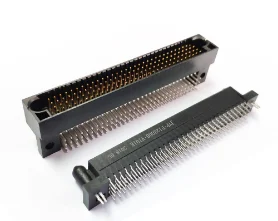

Specifications

| Component Type | 24-pin eatx power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 8 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.How important is the overall quality of a 24-pin eatx power connector?

Being one of the top 24-pin eatx power connector manufacturers in China, We attach great importance to this detail. The overall quality of a power connector is very important. Poor quality connectors can cause electrical problems, such as shorts, arcing, and overheating, which can lead to equipment failure or even fire. High-quality connectors are designed to provide reliable, safe connections and are built to last.

2.About 24-pin eatx power connector delivery date

The delivery date for power connectors will depend on the type of connector, the quantity, and the supplier. Generally, most suppliers will provide an estimated delivery date when the order is placed. If the order is urgent, some suppliers may be able to provide a faster delivery time.

3.About 24-pin eatx power connector R&D capabilities

Power connector R&D capabilities vary from company to company. Some companies specialize in developing custom power connectors for specific applications, while others may have a more general focus on developing power connectors for a variety of applications. Companies may also specialize in developing power connectors for specific industries, such as automotive, medical, or industrial. Additionally, some companies may have the capability to develop power connectors with specific features, such as waterproofing or high-temperature resistance. Companies may also have the capability to develop power connectors with specific certifications, such as UL or CE.

4.Are there any options for PCB mount or panel mount 24-pin eatx power connectors?

Yes, there are a variety of power connectors available for PCB mount and panel mount applications. These include Molex, JST, Phoenix, and Amphenol connectors.

5.What are the main components of a 24-pin eatx power connector?

We are a professional 24-pin eatx power connector company dedicated to providing high quality products and services. The main components of a power connector are the housing, contacts, and strain relief. The housing is the outer shell of the connector that holds the contacts and strain relief in place. The contacts are the electrical terminals that make contact with the mating connector. The strain relief is a flexible material that helps to secure the cable to the connector and prevents it from being pulled out.

6.What kind of material is commonly used for making 24-pin eatx power connectors?

We focus on innovation and continuous improvement to maintain a competitive advantage. Power connectors are typically made from metals such as copper, aluminum, and brass, as well as plastics such as nylon and polycarbonate.

7.About 24-pin eatx power connector origin

The origin of power connectors can be traced back to the early days of electricity. In the late 19th century, the first electrical connectors were developed to connect electrical devices to power sources. These connectors were made of metal and were designed to be inserted into a socket. Over time, the design of power connectors has evolved to include a variety of shapes and sizes to accommodate different types of electrical devices. Today, power connectors are used in a wide range of applications, from consumer electronics to industrial machinery.

8.About the development history of 24-pin eatx power connector factory

The power connector factory was established in the early 1990s. It was founded by a group of experienced engineers and technicians who had been working in the connector industry for many years. The company has grown steadily over the years and has become one of the leading manufacturers of power connectors in the world. The company has developed a wide range of products, including power connectors, power cords, and power adapters. The company has also developed a range of custom solutions for customers, including custom-designed connectors and custom-made power cords. The company has also developed a range of innovative products, such as the Power Connector System, which is designed to provide a reliable and efficient connection between power sources and devices. The company has also developed a range of products for the automotive industry, including power connectors for cars, trucks, and motorcycles. The company has also developed a range of products for the medical industry, including power connectors for medical equipment.

9.What is the purpose of a 24-pin eatx power connector?

We operate our 24-pin eatx power connector business with integrity and honesty. A power connector is used to connect a power source to an electrical device. It is used to provide power to the device and to protect the device from power surges.

10.About 24-pin eatx power connector MOQ

The MOQ for power connectors will depend on the type of connector and the supplier. Generally, the MOQ for power connectors is between 500 and 1000 pieces. However, some suppliers may offer lower MOQs depending on the type of connector and the quantity required.

11.How does impedance affect the performance of a 24-pin eatx power connector?

As one of the 24-pin eatx power connector market leaders, we are known for innovation and reliability. Impedance affects the performance of a power connector by limiting the amount of current that can flow through the connector. If the impedance is too high, the connector will not be able to handle the amount of current needed to power the device. If the impedance is too low, the connector will be overloaded and may cause damage to the device.

12.How do you prevent the pins on a 24-pin eatx power connector from getting damaged?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Inspect the pins for any damage before connecting the power connector. 2. Make sure the pins are aligned correctly before connecting the power connector. 3. Use a connector with a locking mechanism to ensure the pins stay in place. 4. Use a connector with a dust cover to protect the pins from dirt and debris. 5. Use a connector with a strain relief to reduce the stress on the pins. 6. Use a connector with a flexible cable to reduce the strain on the pins. 7. Use a connector with a protective sleeve to reduce the risk of pin damage. 8. Use a connector with a protective cap to reduce the risk of pin damage. 9. Use a connector with a protective shield to reduce the risk of pin damage. 10. Handle the connector with care to avoid any accidental damage to the pins.

13.Are there any options for waterproof or dustproof 24-pin eatx power connectors?

As one of the top 24-pin eatx power connector manufacturers in China, we take this very seriously. Yes, there are several options for waterproof and dustproof power connectors. These include IP67 rated connectors, which are designed to be waterproof and dustproof, as well as waterproof and dustproof cable glands, which are designed to protect cables from water and dust. Additionally, there are several types of waterproof and dustproof junction boxes, which are designed to protect electrical connections from water and dust.

14.Can 24-pin eatx power connectors be used for medical equipment?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Yes, power connectors can be used for medical equipment. However, it is important to ensure that the connectors are rated for medical use and meet the necessary safety standards.

15.Can 24-pin eatx power connectors be used in harsh environments?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can be used in harsh environments. Many power connectors are designed to be durable and resistant to extreme temperatures, dust, moisture, and other environmental factors.

16.How do you determine the appropriate wire gauge for a 24-pin eatx power connector?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. The appropriate wire gauge for a power connector is determined by the current rating of the connector. The current rating is usually printed on the connector itself, and the wire gauge should be chosen to ensure that the current rating is not exceeded. The National Electrical Code (NEC) provides tables that list the maximum current rating for different wire gauges.

Tag:2 pin power connector motherboard,4 pin pc power connector,round power connector,power connector 5.5 x 2.1 mm,atx 12v cpu power connector