MedlonUploaded:2023-11-27Browse:2240

Shenzhen Metron Hardware Products Co., Ltd. is a leading manufacturer of power connectors whose products are used in many industries such as telecommunications, military, and aerospace. With over 10 years of experience, Medlon offers a diverse portfolio of high-quality power connectors known for their reliability and durability.

We have a professional team, including mold room, stamping department, injection molding department, and assembly department, forming an integrated management model from product design, development, manufacturing, and sales. Medlon also provides customers with connector design solutions, aiming to achieve synchronized development with customers and establish good cooperative relationships with customers. Power connectors come in various sizes and specifications to suit different electrical and electronic devices. A popular power connector model is the Molex Mini-Fit Jr 5559 series, with a rated voltage of 600V and a current carrying capacity of up to 9A per circuit. It has a compact design, with a pitch of 4.2mm and a height of only 8.00mm, making it suitable for tight spaces.

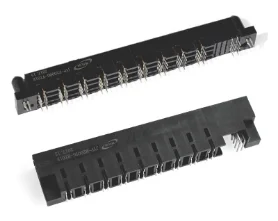

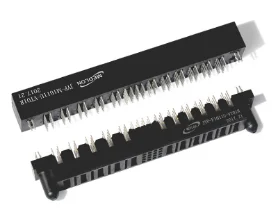

This power connector also features polarized housings to prevent misalignment when mating, as well as a positive lock to ensure secure connections. With a temperature range of -40°C to +105°C, the Molex Mini-Fit Jr 5559 series is a reliable and efficient choice for power delivery in a wide range of applications. power connector have spring contact, it is integration, small size, high power current conduction capability, contact smoothly, mate with guide position, high connect stabilization. The contact is high performance copper alloy, gold plated at mating area. Housing is high heat-resisting thermoplastic, glass filled, UL94-V0, Black. The contacts include power contact and signal contact, The distance of power contacts is 5.08mm, 6.35mm, 7.62mm, The quantity and sequence of the power and signal contacts could be ranged by the customer, at the same outer size of the connector.

about 2 pin dc power connector, we have carefully prepared some relevant professional knowledge documents for you, hoping to provide some help to you who are interested in usb power connector.

Powering up your devices has never been easier with our top-of-the-line power connector solutions. We understand the frustration of constantly having to switch out cables and adapters just to keep your devices charged. That's why we have curated a collection of the best power connectors, ensuring compatibility with all your devices. Whether you're at home, in the office, or on the go, our connectors are designed to provide fast and efficient charging so you can always stay connected. Don't let a dying battery slow you down. Power up with our reliable and convenient power connector solutions today.

At our company, we aim to simplify the process of connecting with our advanced power connectors. Our connectors are designed to provide a seamless and efficient way to power and connect various devices, making your life easier and more convenient. With our innovative technology and superior quality materials, our power connectors offer reliable and stable connections, ensuring that your devices receive the power they need. Trust in our simplified approach to connections and let us help streamline your daily tasks.

1.About power connector overseas warehouse

Power connector overseas warehouses are warehouses located in foreign countries that store power connectors and related components. These warehouses are used to store and distribute power connectors to customers in different countries. They are typically located near major ports and airports, allowing for easy access to international customers. Power connector overseas warehouses are beneficial for companies that need to ship power connectors to customers in different countries quickly and efficiently.

2.About power connector production skills training

Power connector production skills training is designed to help workers learn the skills needed to produce power connectors. This type of training typically covers topics such as the types of power connectors available, the tools and materials needed to produce them, and the steps involved in the production process. It may also include instruction on safety protocols and quality control measures. The goal of this type of training is to ensure that workers are able to produce power connectors that meet industry standards and customer requirements.

3.About power connector quality system

A power connector quality system is a set of processes and procedures that are used to ensure the quality of power connectors. This system includes the design, manufacture, testing, and maintenance of power connectors. It also includes the inspection and certification of power connectors to ensure they meet the required standards. The system also includes the tracking and monitoring of power connector performance over time. The system should also include the development of corrective action plans to address any issues that arise.

4.What is the typical voltage and current rating for power connectors?

The typical voltage and current rating for power connectors depends on the type of connector being used. For example, a standard IEC 60320 C13 connector is rated for 10A at 250V.

5.How do you select the appropriate locking mechanism for a power connector?

1. Consider the application: The type of locking mechanism you choose should be based on the application and the environment in which the power connector will be used. For example, if the connector will be used in a harsh environment, you may want to choose a locking mechanism that is more robust and resistant to corrosion. 2. Consider the size: The size of the power connector should also be taken into account when selecting a locking mechanism. If the connector is too small, then a locking

6.About power connector patent

A power connector patent is a type of patent that covers the design and/or function of a power connector. This type of patent is typically used to protect the design of a power connector from being copied or used without permission. It can also be used to protect the function of a power connector, such as the way it connects to a power source or the way it transmits power. Power connector patents can be used to protect a wide range of products, from small electronic devices to large industrial

7.How do you ensure a secure and reliable connection with a power connector?

1. Use a connector with a locking mechanism to ensure a secure connection. 2. Inspect the connector and cable for any signs of damage or wear before connecting. 3. Use a connector with a high current rating to ensure it can handle the power requirements of the device. 4. Use a connector with a high voltage rating to ensure it can handle the voltage requirements of the device. 5. Use a connector with a high temperature rating to ensure it can

8.Can power connectors support high-frequency signals?

Yes, power connectors can support high-frequency signals. However, the type of connector used will depend on the specific application and the frequency of the signal. For example, coaxial connectors are often used for high-frequency signals, while screw terminals are better suited for lower-frequency signals.

9.Is there a specific sequence for connecting and disconnecting a power connector?

Yes, there is a specific sequence for connecting and disconnecting a power connector. The sequence is as follows: 1. Disconnect the power source from the device. 2. Disconnect the power connector from the device. 3. Inspect the power connector for any damage or corrosion. 4. Connect the power connector to the device. 5. Reconnect the power source to the device. 6. Test the device to ensure proper operation

10.Can power connectors be used for data transmission as well?

No, power connectors are not designed for data transmission. They are designed to carry electrical power from one device to another. Data transmission requires a different type of connector, such as an Ethernet or USB connector.

11.How do you determine the appropriate wire gauge for a power connector?

The appropriate wire gauge for a power connector is determined by the current rating of the connector. The current rating is usually printed on the connector itself, and the wire gauge should be chosen to ensure that the current rating is not exceeded. The National Electrical Code (NEC) provides tables that list the maximum current rating for various wire gauges.

12.Are there any environmentally-friendly options for power connectors?

Yes, there are several environmentally-friendly options for power connectors. These include connectors made from recycled materials, connectors with low-impact manufacturing processes, and connectors with low-emission designs. Additionally, some connectors are designed to be more energy efficient, reducing the amount of energy used during operation.

13.Are there any options for waterproof or dustproof power connectors?

Yes, there are several options for waterproof and dustproof power connectors. These include IP67 rated connectors, which are designed to be waterproof and dustproof, as well as waterproof and dustproof cable glands, which are designed to protect cables from water and dust. Additionally, there are several types of waterproof and dustproof junction boxes, which are designed to protect electrical connections from water and dust.

14.Are there any color code standards for different power connectors?

Yes, there are color code standards for different power connectors. The most common color code standards are the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). The IEC color code standard is used for international power connectors, while the NEMA color code standard is used for North American power connectors.

15.Are there any specific considerations when using power connectors for industrial applications?

Yes, there are several considerations when using power connectors for industrial applications. These include: 1. Ensuring the connectors are rated for the voltage and current requirements of the application. 2. Ensuring the connectors are rated for the environmental conditions of the application. 3. Ensuring the connectors are compatible with the mating connectors used in the application. 4. Ensuring the connectors are designed to meet the safety requirements of the application. 5. Ens

16.About power connector production management system

Power connector production management system is a software solution designed to help manufacturers manage the production of power connectors. It provides a comprehensive set of tools to help streamline the production process, from design and engineering to production and quality control. The system can be used to track production orders, monitor inventory levels, and manage the production process. It also provides detailed reports and analytics to help manufacturers make informed decisions about their production processes. The system can be integrated with other systems, such as ERP and CAD

17.About power connector inventory

Power connector inventory is a type of inventory that is used to track the various types of power connectors that are used in a variety of electronic devices. This type of inventory is important for ensuring that the right type of power connector is available for any given device. It also helps to ensure that the correct type of power connector is used in the correct application. This type of inventory can be used to track the quantity of each type of power connector, as well as the type of connector and the manufacturer

18.What is the difference between a straight and a right-angle power connector?

A straight power connector is a type of connector that has two straight sides that are parallel to each other. This type of connector is typically used to connect two devices that are close together. A right-angle power connector is a type of connector that has two sides that are perpendicular to each other. This type of connector is typically used to connect two devices that are farther apart.

19.What are the main safety features of a power connector?

1. Insulation: Power connectors should be insulated to prevent electric shock and short circuits. 2. Grounding: Power connectors should be grounded to protect against electric shock and reduce the risk of fire. 3. Overload Protection: Power connectors should be designed to prevent overloads and protect against damage to the device. 4. Overvoltage Protection: Power connectors should be designed to prevent overvoltage and protect against damage to the device. 5.