feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

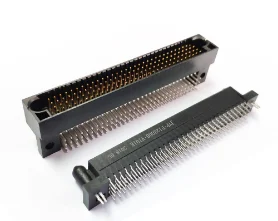

| Component Type | sliding power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 6 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.How do you select the appropriate locking mechanism for a sliding power connector?

1. Consider the application: The type of locking mechanism you choose should be based on the application and the environment in which the power connector will be used. For example, if the connector will be used in a harsh environment, you may want to choose a locking mechanism that is more robust and resistant to corrosion. 2. Consider the size: The size of the power connector should also be taken into account when selecting a locking mechanism. If the connector is too small, then a locking mechanism that is too large may not fit. 3. Consider the cost: The cost of the locking mechanism should also be taken into account when selecting the appropriate locking mechanism for a power connector. If the cost is too high, then it may not be feasible to use the locking mechanism. 4. Consider the safety: The safety of the power connector should also be taken into account when selecting the appropriate locking mechanism. If the locking mechanism is not secure enough, then it could lead to accidental disconnection of the power connector.

2.What are the main components of a sliding power connector?

We are a professional sliding power connector company dedicated to providing high quality products and services. The main components of a power connector are the housing, contacts, and strain relief. The housing is the outer shell of the connector that holds the contacts and strain relief in place. The contacts are the electrical terminals that make contact with the mating connector. The strain relief is a flexible material that helps to secure the cable to the connector and prevents it from being pulled out.

3.Can sliding power connectors be used for high-power applications?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can be used for high-power applications. However, it is important to select the right type of connector for the application, as some connectors are not designed to handle high power levels.

4.Can a sliding power connector handle high temperature and vibration?

Our mission is to provide customers with the best solutions for sliding power connector. Yes, power connectors are designed to handle high temperatures and vibrations. They are typically made of materials such as stainless steel, aluminum, and brass, which are all resistant to high temperatures and vibrations.

5.Are there any options for PCB mount or panel mount sliding power connectors?

Yes, there are a variety of power connectors available for PCB mount and panel mount applications. These include Molex, JST, Phoenix, and Amphenol connectors.

6.Are there any environmentally-friendly options for sliding power connectors?

Our company has many years of sliding power connector experience and expertise. Yes, there are several environmentally-friendly options for power connectors. These include connectors made from recycled materials, connectors with low-impact manufacturing processes, and connectors with low-emission designs. Additionally, some connectors are designed to be more energy efficient, reducing the amount of energy used during operation.

7.Can sliding power connectors be used in high vibration environments, such as in airplanes or trains?

Yes, power connectors can be used in high vibration environments, such as in airplanes or trains. However, it is important to use connectors that are designed to withstand the vibration and shock of the environment. Specialized connectors, such as those with locking mechanisms, are available to ensure a secure connection in these environments.

8.Are there any options for waterproof or dustproof sliding power connectors?

As one of the top sliding power connector manufacturers in China, we take this very seriously. Yes, there are several options for waterproof and dustproof power connectors. These include IP67 rated connectors, which are designed to be waterproof and dustproof, as well as waterproof and dustproof cable glands, which are designed to protect cables from water and dust. Additionally, there are several types of waterproof and dustproof junction boxes, which are designed to protect electrical connections from water and dust.

9.How do you determine the appropriate wire gauge for a sliding power connector?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. The appropriate wire gauge for a power connector is determined by the current rating of the connector. The current rating is usually printed on the connector itself, and the wire gauge should be chosen to ensure that the current rating is not exceeded. The National Electrical Code (NEC) provides tables that list the maximum current rating for different wire gauges.

10.Do sliding power connectors have a maximum number of mating cycles?

As one of the top sliding power connector manufacturers in China, we take this very seriously. Yes, power connectors typically have a maximum number of mating cycles. This number can vary depending on the type of connector and the manufacturer, but is typically between 500 and 1000 cycles.

11.Can sliding power connectors handle power surges or fluctuations?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can handle power surges or fluctuations. However, it is important to use the correct type of power connector for the application. Some power connectors are designed to handle higher levels of power surges or fluctuations than others.

12.Is it possible to customize the design or length of a sliding power connector?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Yes, it is possible to customize the design or length of a power connector. Many companies offer custom power connectors that can be designed to meet specific requirements. These custom connectors can be designed to fit a variety of applications and can be made in different lengths, shapes, and sizes.

13.How important is proper grounding for sliding power connectors?

As one of the top sliding power connector manufacturers in China, we take this very seriously. Proper grounding for power connectors is extremely important. It helps to protect against electric shock, reduce interference, and ensure that the electrical system is functioning properly. Without proper grounding, the power connectors can become damaged or cause a fire hazard.

14.About sliding power connector customization services

Power connector customization services are available from a variety of companies. These services allow customers to design and order custom power connectors that meet their specific needs. Companies that offer these services typically provide a wide range of options, including different sizes, shapes, and materials. Customers can also choose from a variety of colors and finishes. The customization process typically involves providing the company with detailed specifications, such as the type of connector, the number of pins, and the desired voltage and current ratings. The company then designs and manufactures the connector according to the customer’s specifications. Once the connector is complete, it is shipped to the customer for installation.

15.Can sliding power connectors support high-frequency signals?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can support high-frequency signals. However, the type of connector used will depend on the specific application and the frequency of the signal. For example, coaxial connectors are often used for high-frequency signals, while screw terminals are better suited for lower-frequency signals.

16.How do you identify the proper orientation for a sliding power connector?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. The proper orientation for a power connector can be identified by looking at the shape of the connector and the corresponding port. The shape of the connector should match the shape of the port, and the pins should line up with the holes in the port. Additionally, the connector should have a notch or other indicator that shows which side should be facing up.

Tag:cd rom power connector,4 pin atx power connector power supply,8 pin 12 volt power connector