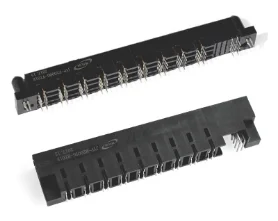

feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

| Type: | rtx 4090 power connector | Packaging Details: | carton |

| Application: | Electric equipment | Supply Ability: | 10558 Piece/Pieces per Week |

| Place of Origin: | Chian,shenzhen | Port: | shenzhen |

| Brand Name: | Medlon | Quantity (pieces): | > 985 |

| Model Number: | Customized options | Lead time (days): | To be negotiated |

| Contact barrel wire size: | 4-11AWG 13.3-3.3m㎡ | Feature: | makes assembly quick and easy |

| AVG contact resistance: | <220 | system: | Flat wiping contact system |

| Contact material: | Silver plated copper | Color: | Colored modular housings |

| Voltage rating: | 579V | Application: | Electric vehicles;Medical equipment;Power supply;Electric equipment |

| Rated current: | 60A | MOQ: | 30 |

1.Are there any options for tool-less installation of rtx 4090 power connectors?

Yes, there are several options for tool-less installation of power connectors. These include push-in connectors, twist-lock connectors, and snap-in connectors. Push-in connectors are the most common type of tool-less power connector and are designed to be inserted into a power socket without the need for any tools. Twist-lock connectors are also available and are designed to be twisted into place. Finally, snap-in connectors are designed to be snapped into place without the need for any tools.

2.What is the maximum temperature that a rtx 4090 power connector can withstand?

We have established a good reputation and reliable partnerships within the rtx 4090 power connector industry. The maximum temperature that a power connector can withstand depends on the type of connector and the materials used in its construction. Generally, power connectors are designed to withstand temperatures up to 125°C (257°F).

3.About rtx 4090 power connector customization services

Power connector customization services are available from a variety of companies. These services allow customers to design and order custom power connectors that meet their specific needs. Companies that offer these services typically provide a wide range of options, including different sizes, shapes, and materials. Customers can also choose from a variety of colors and finishes. The customization process typically involves providing the company with detailed specifications, such as the type of connector, the number of pins, and the desired voltage and current ratings. The company then designs and manufactures the connector according to the customer’s specifications. Once the connector is complete, it is shipped to the customer for installation.

4.About rtx 4090 power connector production equipment

Power connector production equipment is used to manufacture power connectors for a variety of applications. This equipment is used to create a variety of power connectors, including those used in automotive, industrial, and consumer electronics. The equipment typically includes a variety of machines, such as presses, injection molding machines, and die-casting machines. The machines are used to create the various components of the power connectors, such as the contacts, housings, and terminals. The equipment is also used to assemble the components into the finished product.

5.Is there a specific sequence for connecting and disconnecting a rtx 4090 power connector?

As one of the rtx 4090 power connector market leaders, we are known for innovation and reliability. Yes, there is a specific sequence for connecting and disconnecting a power connector. The sequence is as follows: 1. Disconnect the power source from the device. 2. Disconnect the power connector from the device. 3. Inspect the power connector for any damage or corrosion. 4. Connect the power connector to the device. 5. Reconnect the power source to the device. 6. Test the device to ensure proper operation.

6.How important is the overall quality of a rtx 4090 power connector?

Being one of the top rtx 4090 power connector manufacturers in China, We attach great importance to this detail. The overall quality of a power connector is very important. Poor quality connectors can cause electrical problems, such as shorts, arcing, and overheating, which can lead to equipment failure or even fire. High-quality connectors are designed to provide reliable, safe connections and are built to last.

7.Can rtx 4090 power connectors be used for high-power applications?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can be used for high-power applications. However, it is important to select the right type of connector for the application, as some connectors are not designed to handle high power levels.

8.How important is proper grounding for rtx 4090 power connectors?

As one of the top rtx 4090 power connector manufacturers in China, we take this very seriously. Proper grounding for power connectors is extremely important. It helps to protect against electric shock, reduce interference, and ensure that the electrical system is functioning properly. Without proper grounding, the power connectors can become damaged or cause a fire hazard.

9.Can rtx 4090 power connectors be used for medical equipment?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Yes, power connectors can be used for medical equipment. However, it is important to ensure that the connectors are rated for medical use and meet the necessary safety standards.

10.Can rtx 4090 power connectors be quickly and easily disconnected?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, power connectors can be quickly and easily disconnected. Many types of power connectors feature a quick-release mechanism that allows them to be disconnected with minimal effort.

11.Are there any specific considerations when using rtx 4090 power connectors for industrial applications?

As one of the rtx 4090 power connector market leaders, we are known for innovation and reliability. Yes, there are several considerations when using power connectors for industrial applications. These include: 1. Ensuring the connectors are rated for the voltage and current requirements of the application. 2. Ensuring the connectors are rated for the environmental conditions of the application. 3. Ensuring the connectors are compatible with the mating connectors used in the application. 4. Ensuring the connectors are designed to meet the safety requirements of the application. 5. Ensuring the connectors are designed to meet the durability requirements of the application. 6. Ensuring the connectors are designed to meet the EMI/RFI requirements of the application.

12.What is the purpose of a rtx 4090 power connector?

We operate our rtx 4090 power connector business with integrity and honesty. A power connector is used to connect a power source to an electrical device. It is used to provide power to the device and to protect the device from power surges.

13.What are the main safety features of a rtx 4090 power connector?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Insulation: Power connectors should be insulated to prevent electric shock and short circuits. 2. Grounding: Power connectors should be grounded to protect against electric shock and reduce the risk of fire. 3. Overload Protection: Power connectors should be designed to prevent overloads and protect against damage to the device. 4. Overvoltage Protection: Power connectors should be designed to prevent overvoltage and protect against damage to the device. 5. Short Circuit Protection: Power connectors should be designed to prevent short circuits and protect against damage to the device. 6. Surge Protection: Power connectors should be designed to protect against power surges and protect against damage to the device.

Tag:usb power connector,6 pin vga power connector,led strip light power connector,6900 xt power connector