MedlonUploaded:2023-06-14Browse:8560

The main application field of the round connector

Round connectors are used in a variety of applications, including automotive, industrial, and consumer electronics. They are commonly used to connect electrical components, such as motors, sensors, and switches. They are also used to connect cables and wires in audio and video systems, as well as in telecommunications and computer networks. Round connectors are also used in medical equipment, such as MRI machines and X-ray machines.

What is a round connector?

A round connector is a type of electrical connector that has a circular shape. It is typically used to connect two wires or cables together, and is often used in audio, video, and data applications. Round connectors are available in a variety of sizes and styles, including coaxial, DIN, and mini-DIN. They are also available in a variety of materials, such as plastic, metal, and rubber. Round connectors are often used in automotive, industrial, and consumer electronics applications.

Why do we need round connector?

Round connectors are used to connect two or more wires together in a secure and reliable way. They are often used in electrical and electronic applications, such as in the automotive industry, where they are used to connect wires to components like sensors, switches, and motors. Round connectors are also used in the telecommunications industry to connect cables to routers and other networking equipment.

Inventor of the round connector

The round connector was invented by the American electrical engineer, Carl E. Paul, in the early 1900s. He developed the round connector as a way to connect electrical wires without the need for soldering. The round connector is also known as the "Paul connector" in his honor.

The development trend of the round connector industry

The round connector industry is expected to experience significant growth in the coming years. This is due to the increasing demand for high-performance connectors in a variety of applications, such as automotive, industrial, and consumer electronics. The industry is also expected to benefit from the increasing demand for miniaturization and the development of new technologies, such as high-speed data transmission. Additionally, the industry is expected to benefit from the increasing demand for wireless connectivity solutions, as well as the development of new materials and technologies for improved performance.

History of round connector development

The round connector has been in use since the early 19th century. The first round connectors were used in the telegraph industry, and were made of brass or copper. These connectors were used to connect the wires of the telegraph system.

In the early 20th century, round connectors were used in the telephone industry. These connectors were made of plastic and were used to connect the wires of the telephone system.

In the 1950s, round connectors were used in the automotive industry. These connectors were made of metal and were used to connect the wires of the car's electrical system.

In the 1970s, round connectors were used in the computer industry. These connectors were made of plastic and were used to connect the wires of the computer's internal components.

In the 1980s, round connectors were used in the consumer electronics industry. These connectors were made of plastic and were used to connect the wires of the consumer electronics devices.

Today, round connectors are used in a variety of industries, including automotive, computer, consumer electronics, and telecommunications. They are made of a variety of materials, including plastic, metal, and fiber optics.

When did humans start using round connector?

The first round electrical connectors were developed in the late 19th century. The first patent for a round electrical connector was issued in 1891.

What are the classifications of round connector?

1. Circular Connectors: These are the most common type of round connector and are used in a variety of applications. They are available in a variety of sizes and configurations, including bayonet, threaded, and push-pull.

2. Coaxial Connectors: These are used to connect coaxial cables and are available in a variety of sizes and configurations.

3. Fiber Optic Connectors: These are used to connect fiber optic cables and are available in a variety of sizes and configurations.

4. D-Sub Connectors: These are used to connect computer and other electronic devices and are available in a variety of sizes and configurations.

5. USB Connectors: These are used to connect USB cables and are available in a variety of sizes and configurations.

What material is suitable for round connector

Round connectors can be made from a variety of materials, including plastic, metal, and rubber. Plastic is the most common material used for round connectors, as it is lightweight, durable, and cost-effective. Metal connectors are more expensive but offer greater strength and durability. Rubber connectors are often used in applications where vibration or shock is a factor.

How to choose the round connector manufacturer with the best quality?

1. Research the company’s reputation: Check online reviews and customer feedback to get an idea of the company’s reputation.

2. Ask for samples: Ask the company to provide samples of their products so you can test them for quality.

3. Check certifications: Make sure the company is certified by a reputable organization such as UL or CSA.

4. Compare prices: Compare the prices of different manufacturers to ensure you are getting the best value for your money.

5. Ask for references: Ask the company for references from previous customers to get an idea of their customer service.

How can round connector manufacturers improve production quality?

1. Implement quality control systems: Round connector manufacturers should implement quality control systems to ensure that all products meet the required standards. This includes testing the products for any defects or inconsistencies before they are shipped out.

2. Invest in better machinery: Investing in better machinery can help round connector manufacturers produce higher quality products. This includes investing in machines that are designed to produce more precise and accurate parts.

3. Utilize automation: Automation can help round connector manufacturers reduce errors and improve production quality. Automation can also help reduce labor costs and increase efficiency.

4. Improve training: Training employees on the proper use of machinery and techniques can help round connector manufacturers produce higher quality products.

5. Invest in research and development: Investing in research and development can help round connector manufacturers stay ahead of the competition and develop new and improved products.

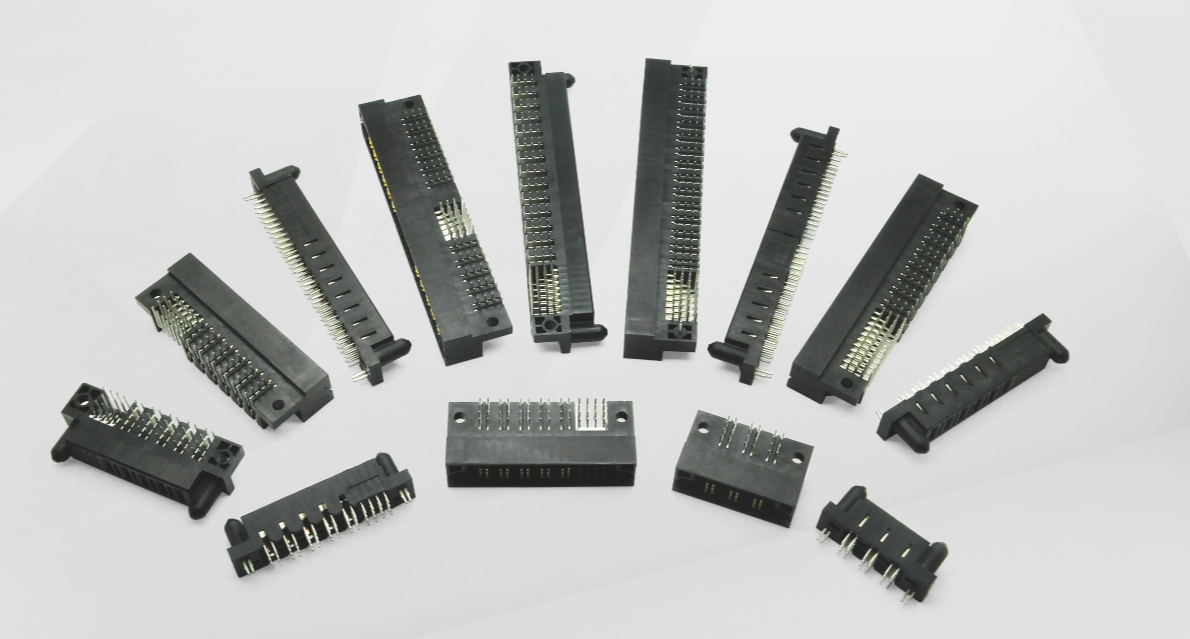

What products can round connector manufacturers produce?

Round connector manufacturers can produce a wide variety of products, including circular connectors, circular power connectors, circular coaxial connectors, circular RF connectors, circular Ethernet connectors, circular USB connectors, circular D-Sub connectors, circular DIN connectors, circular MIL-Spec connectors, circular automotive connectors, circular audio connectors, circular fiber optic connectors, and circular industrial connectors.

What are the specific requirements of round connector manufacturer?

1. Ability to manufacture connectors to meet customer specifications.

2. Knowledge of the various types of round connectors and their applications.

3. Ability to design and manufacture custom connectors.

4. Ability to provide technical support and troubleshooting.

5. Knowledge of the latest industry standards and regulations.

6. Ability to provide quality assurance and testing services.

7. Ability to provide cost-effective solutions.

8. Ability to provide timely delivery of products.

9. Ability to provide after-sales service and support.

What production equipment do round connector manufacturer need?

Round connector manufacturers typically need a variety of production equipment, including injection molding machines, CNC machines, lathes, presses, and other metalworking equipment. They may also need specialized equipment for testing and quality control, such as microscopes, calipers, and other measuring tools.

Analysis on the layout of round connector manufacturer in China's industrial chain

Round connectors are widely used in various industries, and the layout of round connector manufacturers in China's industrial chain is mainly concentrated in the Pearl River Delta, Yangtze River Delta and Bohai Rim.

In the Pearl River Delta, Shenzhen is the most important production base for round connectors. Shenzhen has a complete industrial chain, from raw material suppliers to finished product manufacturers, and has a large number of professional round connector manufacturers.

In the Yangtze River Delta, Shanghai is the most important production base for round connectors. Shanghai has a complete industrial chain, from raw material suppliers to finished product manufacturers, and has a large number of professional round connector manufacturers.

In the Bohai Rim, Tianjin is the most important production base for round connectors. Tianjin has a complete industrial chain, from raw material suppliers to finished product manufacturers, and has a large number of professional round connector manufacturers.

In addition, there are also some round connector manufacturers in other regions of China, such as Zhejiang, Jiangsu, Shandong, etc. These manufacturers mainly produce low-end round connectors, and their production scale is relatively small.

What is the maintenance content of the round connector manufacturer's production equipment?

1. Regularly check the lubrication of the equipment and add lubricating oil in time.

2. Regularly check the wear of the parts and replace the worn parts in time.

3. Regularly check the electrical components and replace the damaged components in time.

4. Regularly check the tightness of the screws and tighten them in time.

5. Regularly check the cleanliness of the equipment and clean it in time.

6. Regularly check the operation of the equipment and adjust it in time.

7. Regularly check the temperature of the equipment and adjust it in time.

8. Regularly check the safety of the equipment and take measures to ensure safety.

round connector manufacturer produce equipment, how to improve equipment management efficiency

1. Establish a comprehensive equipment management system: Establish a comprehensive equipment management system to ensure that all equipment is properly tracked and managed. This system should include a database of all equipment, a tracking system for maintenance and repairs, and a system for tracking usage and performance.

2. Implement preventive maintenance: Implement a preventive maintenance program to ensure that all equipment is regularly inspected and serviced. This will help to reduce the risk of breakdowns and ensure that the equipment is running at its optimal performance.

3. Utilize technology: Utilize technology to streamline the equipment management process. This could include using software to track and manage equipment, as well as using sensors and other devices to monitor performance and usage.

4. Train staff: Train staff on the proper use and maintenance of the equipment. This will help to ensure that the equipment is being used correctly and that any potential problems are identified and addressed quickly.

5. Monitor performance: Monitor the performance of the equipment to ensure that it is running at its optimal level. This will help to identify any potential problems and allow for quick corrective action.

Production scale and production capacity of round connector manufacturer

The production scale and production capacity of a round connector manufacturer will depend on the size of the company and the type of connectors they produce. Generally, larger companies will have larger production scales and capacities, while smaller companies may have more limited production scales and capacities. The production capacity of a round connector manufacturer will also depend on the type of connectors they produce, as some connectors require more complex manufacturing processes than others. Additionally, the production capacity of a round connector manufacturer may be affected by the availability of raw materials and the number of employees they have.

Advantages and development direction of round connector manufacturers

1. Advantages:

a. High reliability: Round connectors have a simple structure and reliable connection.

b. Easy to install: Round connectors are easy to install and can be used in a variety of applications.

c. Cost-effective: Round connectors are cost-effective and can be used in a variety of applications.

d. Versatility: Round connectors are versatile and can be used in a variety of applications.

2. Development Direction:

a. High-speed transmission: Round connectors manufacturers are developing connectors that can support high-speed transmission.

b. Miniaturization: Round connectors manufacturers are developing connectors that are smaller and more compact.

c. Improved durability: Round connectors manufacturers are developing connectors that are more durable and can withstand harsh environments.

d. Improved performance: Round connectors manufacturers are developing connectors that have improved performance and are more reliable.

Analysis of R&D capabilities of global round connector manufacturer

The research and development (R&D) capabilities of a global round connector manufacturer are an important factor in determining the success of the company. R&D capabilities are the ability of a company to develop new products, processes, and technologies that can be used to improve the company’s products and services. A company’s R&D capabilities can be assessed by looking at the resources it has available for research and development, the number of patents it holds, and the number of new products it has developed.

The resources available for research and development are an important factor in determining the R&D capabilities of a global round connector manufacturer. The company should have access to the latest technology and equipment, as well as a team of experienced engineers and scientists. The company should also have access to a wide range of materials and components, as well as the ability to develop new products and processes.

The number of patents held by a global round connector manufacturer is also an important factor in assessing its R&D capabilities. Patents are a form of intellectual property that protect the company’s inventions and innovations. A company with a large number of patents is likely to have a strong R&D capability, as it is able to protect its innovations and inventions from competitors.

Finally, the number of new products developed by a global round connector manufacturer is also an important factor in assessing its R&D capabilities. A company that is able to develop new products and processes is likely to have a strong R&D capability, as it is able to stay ahead of the competition and provide customers with the latest products and technologies.

Overall, the R&D capabilities of a global round connector manufacturer are an important factor in determining the success of the company. The company should have access to the latest technology and equipment, a team of experienced engineers and scientists, a wide range of materials and components, and a large number of patents. Additionally, the company should be able to develop new products and processes in order to stay ahead of the competition and provide customers with the latest products and technologies.

Matters needing attention in the development of raw material supply chain for round connector manufacturer

1. Establish a reliable raw material supply chain: It is important to establish a reliable raw material supply chain for round connector manufacturers. This includes finding reliable suppliers, negotiating favorable terms, and ensuring that the raw materials are of high quality and delivered on time.

2. Monitor the quality of raw materials: Quality control is essential for round connector manufacturers. It is important to monitor the quality of raw materials to ensure that they meet the required standards.

3. Develop a risk management plan: It is important to develop a risk management plan to mitigate any potential risks associated with the raw material supply chain. This includes identifying potential risks, assessing their impact, and developing strategies to mitigate them.

4. Establish a pricing strategy: It is important to establish a pricing strategy for raw materials to ensure that the cost of production is kept low. This includes negotiating favorable terms with suppliers and ensuring that the prices are competitive.

5. Develop a logistics plan: It is important to develop a logistics plan to ensure that the raw materials are delivered on time. This includes identifying the most efficient routes, negotiating favorable terms with carriers, and ensuring that the delivery times are met.

Instructions for cooperation with round connector manufacturer

1. Establish a clear communication channel: Establish a clear communication channel with the round connector manufacturer to ensure that all parties involved are aware of the project requirements and expectations.

2. Define the scope of the project: Clearly define the scope of the project, including the type of round connector, the quantity, and the timeline for delivery.

3. Negotiate a price: Negotiate a price with the round connector manufacturer that is fair and reasonable for both parties.

4. Establish a timeline: Establish a timeline for the project, including the delivery date and any milestones that need to be met.

5. Monitor progress: Monitor the progress of the project to ensure that the round connector manufacturer is meeting the agreed-upon timeline and quality standards.

6. Finalize the project: Once the project is complete, review the results with the round connector manufacturer and finalize the project.

round connector manufacturer production technology coverage

The production technology for circular connectors varies depending on the manufacturer. Generally, the production process involves injection molding, stamping, machining, and assembly. Injection molding is used to create the plastic housing for the connector, while stamping is used to create the metal contacts. Machining is used to create the threads and other features on the connector, and assembly is used to assemble the components together.

Detailed explanation of the production process of round connector

1. Molding: The round connector is made by injection molding. The molding process includes the injection of molten plastic into a mold cavity, where it cools and solidifies into the desired shape.

2. Assembly: After the round connector is molded, it is then assembled with other components such as pins, terminals, and wires. The assembly process involves connecting the components together and ensuring that they are securely fastened.

3. Testing: After the round connector is assembled, it is then tested to ensure that it meets the required specifications. This includes testing for electrical continuity, insulation resistance, and other parameters.

4. Packaging: After the round connector is tested, it is then packaged for shipment. The packaging process involves placing the connector in a protective bag or box and labeling it with the necessary information.