feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

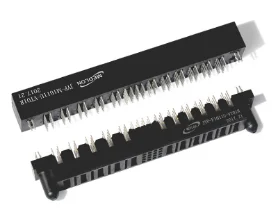

| Type: | pci power connector | Packaging Details: | carton |

| Application: | Electric equipment | Supply Ability: | 9304 Piece/Pieces per Week |

| Place of Origin: | Chian,shenzhen | Port: | shenzhen |

| Brand Name: | Medlon | Quantity (pieces): | > 962 |

| Model Number: | Customized options | Lead time (days): | To be negotiated |

| Contact barrel wire size: | 6-11AWG 13.3-3.3m㎡ | Feature: | makes assembly quick and easy |

| AVG contact resistance: | <231 | system: | Flat wiping contact system |

| Contact material: | Silver plated copper | Color: | Colored modular housings |

| Voltage rating: | 529V | Application: | Electric vehicles;Medical equipment;Power supply;Electric equipment |

| Rated current: | 45A | MOQ: | 30 |

1.Are there any environmentally-friendly options for pci power connectors?

Our company has many years of pci power connector experience and expertise. Yes, there are several environmentally-friendly options for power connectors. These include connectors made from recycled materials, connectors with low-impact manufacturing processes, and connectors with low-emission designs. Additionally, some connectors are designed to be more energy efficient, reducing the amount of energy used during operation.

2.Are there any options for angled or curved pci power connectors?

Our company has many years of pci power connector experience and expertise. Yes, there are angled and curved power connectors available. These connectors are typically used in tight spaces or when the power cable needs to be routed around an obstacle. Examples of angled and curved power connectors include right angle connectors, elbow connectors, and flexible connectors.

3.About pci power connector warranty

Power connector warranties vary depending on the manufacturer. Generally, power connectors are covered by a limited warranty that covers defects in materials and workmanship for a specified period of time. The warranty period may range from one year to five years, depending on the manufacturer. Some manufacturers may also offer extended warranties for their power connectors. It is important to read the warranty information carefully before purchasing a power connector to ensure that it is covered by the warranty.

4.Are there any color code standards for different pci power connectors?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, there are color code standards for different power connectors. The most common color code standards are the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). The IEC color code standard is used for most European countries, while the NEMA color code standard is used in the United States.

5.Can pci power connectors support high-frequency signals?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can support high-frequency signals. However, the type of connector used will depend on the specific application and the frequency of the signal. For example, coaxial connectors are often used for high-frequency signals, while screw terminals are better suited for lower-frequency signals.

6.About pci power connector patent

A power connector patent is a type of patent that covers the design and/or function of a power connector. This type of patent is typically used to protect the design of a power connector from being copied or used without permission. It can also be used to protect the function of a power connector, such as the way it connects to a power source or the way it transmits power. Power connector patents can be used to protect a wide range of products, from small electronic devices to large industrial machines.

7.How do you ensure a secure and reliable connection with a pci power connector?

pci power connector is not a product only, but also can help you comes to money-making. 1. Use a connector with a locking mechanism to ensure a secure connection. 2. Inspect the connector and cable for any signs of damage or wear before connecting. 3. Use a connector with a high current rating to ensure it can handle the power requirements of the device. 4. Use a connector with a high voltage rating to ensure it can handle the voltage requirements of the device. 5. Use a connector with a high temperature rating to ensure it can handle the temperature requirements of the device. 6. Use a connector with a high dielectric strength rating to ensure it can handle the electrical requirements of the device. 7. Use a connector with a high insulation resistance rating to ensure it can handle the electrical requirements of the device. 8. Use a connector with a high contact resistance rating to ensure it can handle the electrical requirements of the device. 9. Use a connector with a high vibration resistance rating to ensure it can handle the mechanical requirements of the device. 10. Use a connector with a high shock resistance rating to ensure it can handle the mechanical requirements of the device.

8.Can pci power connectors be used for high-power applications?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can be used for high-power applications. However, it is important to select the right type of connector for the application, as some connectors are not designed to handle high power levels.

9.What is the difference between a straight and a right-angle pci power connector?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. A straight power connector is a type of connector that has two straight sides that are parallel to each other. This type of connector is typically used to connect two devices that are close together. A right-angle power connector is a type of connector that has two sides that are perpendicular to each other. This type of connector is typically used to connect two devices that are farther apart.

10.Can pci power connectors handle high voltages?

Being one of the top pci power connector manufacturers in China, We attach great importance to this detail. No, power connectors are not designed to handle high voltages. High voltage applications require specialized connectors that are designed to safely handle the high voltage.

11.How do you prevent the pins on a pci power connector from getting damaged?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Inspect the pins for any damage before connecting the power connector. 2. Make sure the pins are aligned correctly before connecting the power connector. 3. Use a connector with a locking mechanism to ensure the pins stay in place. 4. Use a connector with a dust cover to protect the pins from dirt and debris. 5. Use a connector with a strain relief to reduce the stress on the pins. 6. Use a connector with a flexible cable to reduce the strain on the pins. 7. Use a connector with a protective sleeve to reduce the risk of pin damage. 8. Use a connector with a protective cap to reduce the risk of pin damage. 9. Use a connector with a protective shield to reduce the risk of pin damage. 10. Handle the connector with care to avoid any accidental damage to the pins.

12.Can pci power connectors be used in harsh environments?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can be used in harsh environments. Many power connectors are designed to be durable and resistant to extreme temperatures, dust, moisture, and other environmental factors.

13.About pci power connector MOQ

The MOQ for power connectors will depend on the type of connector and the supplier. Generally, the MOQ for power connectors is between 500 and 1000 pieces. However, some suppliers may offer lower MOQs depending on the type of connector and the quantity required.

14.Is there a risk of electrical shock when handling pci power connectors?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, there is a risk of electrical shock when handling power connectors. It is important to make sure that all power connectors are properly insulated and that all safety precautions are taken when handling them.

15.Are there any options for waterproof or dustproof pci power connectors?

As one of the top pci power connector manufacturers in China, we take this very seriously. Yes, there are several options for waterproof and dustproof power connectors. These include IP67 rated connectors, which are designed to be waterproof and dustproof, as well as waterproof and dustproof cable glands, which are designed to protect cables from water and dust. Additionally, there are several types of waterproof and dustproof junction boxes, which are designed to protect electrical connections from water and dust.

Tag:iphone 15 power connector,rtx 4080 power connector,6 pin motherboard power connector,8-pin eps power connector