feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

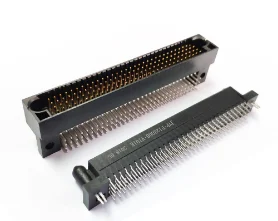

| Component Type | motherboard 4 pin power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 8 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.What is the difference between a straight and a right-angle motherboard 4 pin power connector?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. A straight power connector is a type of connector that has two straight sides that are parallel to each other. This type of connector is typically used to connect two devices that are close together. A right-angle power connector is a type of connector that has two sides that are perpendicular to each other. This type of connector is typically used to connect two devices that are farther apart.

2.How does the operating temperature range affect the performance of a motherboard 4 pin power connector?

The operating temperature range of a power connector affects its performance in several ways. Higher temperatures can cause the connector to become brittle and more prone to cracking or breaking. Higher temperatures can also cause the connector to expand, which can lead to poor contact between the connector and the mating part. Lower temperatures can cause the connector to become stiff and difficult to insert or remove. Additionally, lower temperatures can cause the connector to become brittle and more prone to cracking or breaking.

3.Are there any special considerations when using motherboard 4 pin power connectors in high altitude environments?

We are a professional motherboard 4 pin power connector company dedicated to providing high quality products and services. Yes, there are several special considerations when using power connectors in high altitude environments. These include: using connectors with a higher current rating, using connectors with a higher voltage rating, using connectors with a higher temperature rating, using connectors with a higher insulation resistance rating, and using connectors with a higher dielectric strength rating. Additionally, it is important to ensure that the connectors are properly sealed to prevent moisture from entering the connection.

4.About motherboard 4 pin power connector inventory

Power connector inventory is a type of inventory that is used to track the various types of power connectors that are used in a variety of electronic devices. This type of inventory is important for ensuring that the right type of power connector is available for any given device. It also helps to ensure that the correct type of power connector is used in the correct application. This type of inventory can be used to track the quantity of each type of power connector, as well as the type of connector and the manufacturer.

5.What are the main components of a motherboard 4 pin power connector?

We are a professional motherboard 4 pin power connector company dedicated to providing high quality products and services. The main components of a power connector are the housing, contacts, and strain relief. The housing is the outer shell of the connector that holds the contacts and strain relief in place. The contacts are the electrical terminals that make contact with the mating connector. The strain relief is a flexible material that helps to secure the cable to the connector and prevents it from being pulled out.

6.About motherboard 4 pin power connector R&D capabilities

Power connector R&D capabilities vary from company to company. Some companies specialize in developing custom power connectors for specific applications, while others may have a more general focus on developing power connectors for a variety of applications. Companies may also specialize in developing power connectors for specific industries, such as automotive, medical, or industrial. Additionally, some companies may have the capability to develop power connectors with specific features, such as waterproofing or high-temperature resistance. Companies may also have the capability to develop power connectors with specific certifications, such as UL or CE.

7.What is the purpose of a motherboard 4 pin power connector?

We operate our motherboard 4 pin power connector business with integrity and honesty. A power connector is used to connect a power source to an electrical device. It is used to provide power to the device and to protect the device from power surges.

8.What is the maximum temperature that a motherboard 4 pin power connector can withstand?

We have established a good reputation and reliable partnerships within the motherboard 4 pin power connector industry. The maximum temperature that a power connector can withstand depends on the type of connector and the materials used in its construction. Generally, power connectors are designed to withstand temperatures up to 125°C (257°F).

9.About motherboard 4 pin power connector raw materials

Power connector raw materials are typically made from metals such as copper, aluminum, and brass. These metals are chosen for their electrical conductivity, strength, and corrosion resistance. Plastics such as polycarbonate, nylon, and ABS are also used in the construction of power connectors. These materials are chosen for their durability, flexibility, and insulation properties.

10.Are motherboard 4 pin power connectors standardized in terms of size and shape?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. No, power connectors are not standardized in terms of size and shape. Different types of power connectors come in a variety of sizes and shapes, depending on the application.

11.Can a motherboard 4 pin power connector handle high temperature and vibration?

Our mission is to provide customers with the best solutions for motherboard 4 pin power connector. Yes, power connectors are designed to handle high temperatures and vibrations. They are typically made of materials such as stainless steel, aluminum, and brass, which are all resistant to high temperatures and vibrations.

12.How do you determine the appropriate wire gauge for a motherboard 4 pin power connector?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. The appropriate wire gauge for a power connector is determined by the current rating of the connector. The current rating is usually printed on the connector itself, and the wire gauge should be chosen to ensure that the current rating is not exceeded. The National Electrical Code (NEC) provides tables that list the maximum current rating for different wire gauges.

13.How do you select the appropriate locking mechanism for a motherboard 4 pin power connector?

1. Consider the application: The type of locking mechanism you choose should be based on the application and the environment in which the power connector will be used. For example, if the connector will be used in a harsh environment, you may want to choose a locking mechanism that is more robust and resistant to corrosion. 2. Consider the size: The size of the power connector should also be taken into account when selecting a locking mechanism. If the connector is too small, then a locking mechanism that is too large may not fit. 3. Consider the cost: The cost of the locking mechanism should also be taken into account when selecting the appropriate locking mechanism for a power connector. If the cost is too high, then it may not be feasible to use the locking mechanism. 4. Consider the safety: The safety of the power connector should also be taken into account when selecting the appropriate locking mechanism. If the locking mechanism is not secure enough, then it could lead to accidental disconnection of the power connector.

Tag:6 pin to 8 pin cpu power connector,c12 power connector,1 x 8-pin power connector