feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

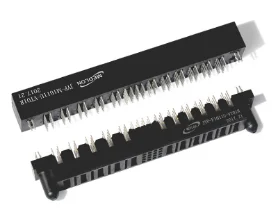

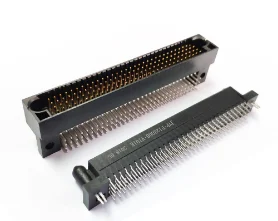

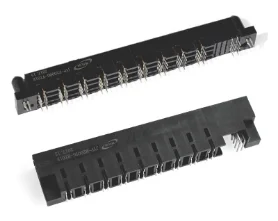

Specifications

| Component Type | how to be a power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 5 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.About how to be a power connector delivery date

The delivery date for power connectors will depend on the type of connector, the quantity, and the supplier. Generally, most suppliers will provide an estimated delivery date when the order is placed. If the order is urgent, some suppliers may be able to provide a faster delivery time.

2.How do you troubleshoot common issues with how to be a power connectors?

Being one of the top how to be a power connector manufacturers in China, We attach great importance to this detail. 1. Check the power source: Make sure the power source is working properly and is providing the correct voltage. 2. Check the power connector: Inspect the power connector for any signs of damage or corrosion. If the connector is damaged, replace it. 3. Check the wiring: Inspect the wiring for any signs of damage or corrosion. If the wiring is damaged, replace it. 4. Check the connection: Make sure the power connector is securely connected to the power source and the device. 5. Check the device: Make sure the device is working properly and is receiving the correct voltage. 6. Check the fuse: If the device is not receiving power, check the fuse to make sure it is not blown. If the fuse is blown, replace it.

3.Are there any security features available for how to be a power connectors?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, there are several security features available for power connectors. These include locking mechanisms, tamper-proof seals, and keyed connectors. Additionally, some power connectors are designed with built-in surge protection to help protect against power surges.

4.Can a how to be a power connector handle high temperature and vibration?

Our mission is to provide customers with the best solutions for how to be a power connector. Yes, power connectors are designed to handle high temperatures and vibrations. They are typically made of materials such as stainless steel, aluminum, and brass, which are all resistant to high temperatures and vibrations.

5.How important is the overall quality of a how to be a power connector?

Being one of the top how to be a power connector manufacturers in China, We attach great importance to this detail. The overall quality of a power connector is very important. Poor quality connectors can cause electrical problems, such as shorts, arcing, and overheating, which can lead to equipment failure or even fire. High-quality connectors are designed to provide reliable, safe connections and are built to last.

6.Can how to be a power connectors handle power surges or fluctuations?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can handle power surges or fluctuations. However, it is important to use the correct type of power connector for the application. Some power connectors are designed to handle higher levels of power surges or fluctuations than others.

7.How do you determine the appropriate wire gauge for a how to be a power connector?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. The appropriate wire gauge for a power connector is determined by the current rating of the connector. The current rating is usually printed on the connector itself, and the wire gauge should be chosen to ensure that the current rating is not exceeded. The National Electrical Code (NEC) provides tables that list the maximum current rating for different wire gauges.

8.How important is proper grounding for how to be a power connectors?

As one of the top how to be a power connector manufacturers in China, we take this very seriously. Proper grounding for power connectors is extremely important. It helps to protect against electric shock, reduce interference, and ensure that the electrical system is functioning properly. Without proper grounding, the power connectors can become damaged or cause a fire hazard.

9.About how to be a power connector production equipment

Power connector production equipment is used to manufacture power connectors for a variety of applications. This equipment is used to create a variety of power connectors, including those used in automotive, industrial, and consumer electronics. The equipment typically includes a variety of machines, such as presses, injection molding machines, and die-casting machines. The machines are used to create the various components of the power connectors, such as the contacts, housings, and terminals. The equipment is also used to assemble the components into the finished product.

10.About how to be a power connector inventory

Power connector inventory is a type of inventory that is used to track the various types of power connectors that are used in a variety of electronic devices. This type of inventory is important for ensuring that the right type of power connector is available for any given device. It also helps to ensure that the correct type of power connector is used in the correct application. This type of inventory can be used to track the quantity of each type of power connector, as well as the type of connector and the manufacturer.

11.Are there any options for PCB mount or panel mount how to be a power connectors?

Yes, there are a variety of power connectors available for PCB mount and panel mount applications. These include Molex, JST, Phoenix, and Amphenol connectors.

12.How does impedance affect the performance of a how to be a power connector?

As one of the how to be a power connector market leaders, we are known for innovation and reliability. Impedance affects the performance of a power connector by limiting the amount of current that can flow through the connector. If the impedance is too high, the connector will not be able to handle the amount of current needed to power the device. If the impedance is too low, the connector will be overloaded and may cause damage to the device.

13.Is there a maximum distance that a how to be a power connector can cover?

how to be a power connector is not a product only, but also can help you comes to money-making. The maximum distance that a power connector can cover depends on the type of connector and the power requirements of the device. Generally, the maximum distance for a power connector is determined by the voltage and current requirements of the device, as well as the type of cable used. For example, a USB cable can typically carry up to 5 volts and 1.5 amps over a distance of up to 5 meters (16 feet).

14.About how to be a power connector MOQ

The MOQ for power connectors will depend on the type of connector and the supplier. Generally, the MOQ for power connectors is between 500 and 1000 pieces. However, some suppliers may offer lower MOQs depending on the type of connector and the quantity required.

15.Are there any special tools or techniques required for installing a how to be a power connector?

Our how to be a power connector products undergo strict quality control to ensure customer satisfaction. Yes, special tools and techniques are required for installing a power connector. Depending on the type of power connector, you may need a crimping tool, soldering iron, wire strippers, and/or heat shrink tubing. Additionally, you may need to use specific techniques such as soldering, crimping, and/or heat shrinking to ensure a secure connection.

16.About how to be a power connector patent

A power connector patent is a type of patent that covers the design and/or function of a power connector. This type of patent is typically used to protect the design of a power connector from being copied or used without permission. It can also be used to protect the function of a power connector, such as the way it connects to a power source or the way it transmits power. Power connector patents can be used to protect a wide range of products, from small electronic devices to large industrial machines.

Tag:bulkhead power connector,motherboard 8 pin power connector,atx 12v power connector,c20 power connector,atx cpu power connector 4 pin to 8 pin