MedlonUploaded:2023-12-05Browse:2961

Shenzhen Metron Hardware Products Co., Ltd., established in 2006, is a leading manufacturer of electrical and electronic connectors (including power connectors). Its products are suitable for various industries such as automotive, medical and consumer electronics. The company is known for its cost-effective and high-quality connectors that comply with international safety standards.

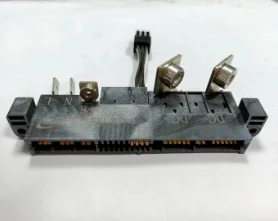

The parameters of a power connector include its current rating, voltage rating, and operating temperature range. These parameters determine the maximum amount of current, voltage, and temperature that the connector can handle, ensuring that the connected device receives the appropriate power supply without causing any damage. Other important parameters include the number of pins, gender (male/female), and size, which vary depending on the type of connector. Featuring a stylish design, this power connector is the perfect solution for all your power requirements. Its small and compact size makes it convenient for home and office use. Say goodbye to bulky and tangled cords, power connectors simplify your space and stay organized.

about 2 pin power connector, we have carefully prepared some relevant professional knowledge documents for you, hoping to provide some help to you who are interested in 2 pin power connector.

Uninterrupted and reliable power supply is essential for our daily lives, whether it's for our homes, offices, or on-the-go needs. That's why we are excited to introduce our range of high-quality and dependable power connectors. Designed to keep you connected and powered on, our connectors cater to a variety of devices and come equipped with advanced safety features. From traditional wall adapters to portable power banks, our products are built to withstand the demands of modern life and ensure that you never run out of power when you need it most. So why settle for less when it comes to powering your devices? Choose our power connectors and stay connected and powered on at all times.

Experience the ultimate in seamless connections with our cutting-edge power connector technology. Unlock the power of uninterrupted productivity and efficiency with our state-of-the-art connectors, designed to provide optimal performance for all your power needs. Say goodbye to clunky, outdated connectors and hello to a world of seamless, reliable connections. Trust in our expertise and discover the difference our innovative technology can make in your day-to-day operations. Upgrade to our power connectors and see the power of seamless connections in action.

1.What are the advantages of using a power connector instead of a wire-to-wire connection?

1. Power connectors provide a secure and reliable connection that is less prone to accidental disconnection. 2. Power connectors are easier to install and require less time and effort than wire-to-wire connections. 3. Power connectors are more resistant to vibration and shock, making them more reliable in harsh environments. 4. Power connectors are more efficient at transferring power, reducing the risk of overheating and fire. 5. Power connectors are more compact and require

2.About power connector production capacity

The production capacity of power connectors depends on the type of connector and the manufacturer. Generally, the production capacity of power connectors is determined by the number of machines and the number of workers available. The production capacity of a single machine is usually limited to a few thousand pieces per day. However, with the help of automation, the production capacity of a single machine can be increased to several hundred thousand pieces per day.

3.Can power connectors be used for medical equipment?

Yes, power connectors can be used for medical equipment. However, it is important to ensure that the connectors are rated for medical use and meet the necessary safety standards.

4.Can power connectors be used for high-power applications?

Yes, power connectors can be used for high-power applications. However, it is important to select the right type of connector for the application, as some connectors are not designed to handle high power levels.

5.How does a power connector differ from a regular electrical connector?

A power connector is designed to carry higher currents than a regular electrical connector. Power connectors are typically used to connect power supplies, motors, and other high-power devices. They are usually larger and sturdier than regular electrical connectors, and they often have additional safety features such as locking mechanisms and strain reliefs.

6.Are there any compatibility issues when using power connectors from different manufacturers?

Yes, there can be compatibility issues when using power connectors from different manufacturers. Different manufacturers may use different sizes, shapes, and pin configurations for their power connectors, which can lead to incompatibility issues. Additionally, some manufacturers may use proprietary connectors that are not compatible with other brands. It is important to check the specifications of the power connectors before purchasing to ensure compatibility.

7.About power connector customization services

Power connector customization services are available from a variety of companies that specialize in the design and manufacture of custom power connectors. These services can include the design and manufacture of custom power connectors for a variety of applications, including medical, industrial, automotive, and consumer electronics. Custom power connectors can be designed to meet specific requirements, such as size, shape, and electrical specifications. Companies that offer power connector customization services can also provide assistance with the selection of the right materials and components for the application. Additionally

8.About power connector R&D capabilities

Power connector R&D capabilities vary from company to company. Some companies specialize in developing custom power connectors for specific applications, while others may have a more general focus on developing power connectors for a variety of applications. Companies may also specialize in developing power connectors for specific industries, such as automotive, medical, or industrial. Additionally, some companies may have the capability to develop power connectors with specific features, such as waterproofing or high-temperature resistance. Companies may also have the capability to develop

9.Can a power connector handle high temperature and vibration?

Yes, power connectors are designed to handle high temperatures and vibrations. They are typically made of materials such as stainless steel, aluminum, and brass, which are all highly resistant to heat and vibration.

10.Can power connectors handle high voltages?

No, power connectors are not designed to handle high voltages. High voltage applications require specialized connectors that are designed to safely handle the high voltage.

11.What are the main safety features of a power connector?

1. Insulation: Power connectors should be insulated to prevent electric shock and short circuits. 2. Grounding: Power connectors should be grounded to protect against electric shock and reduce the risk of fire. 3. Overload Protection: Power connectors should be designed to prevent overloads and protect against damage to the device. 4. Overvoltage Protection: Power connectors should be designed to prevent overvoltage and protect against damage to the device. 5.

12.Are there any special tools or techniques required for installing a power connector?

Yes, special tools and techniques are required for installing a power connector. Depending on the type of power connector, you may need a crimping tool, soldering iron, wire strippers, and/or heat shrink tubing. Additionally, you may need to use specific techniques such as soldering, crimping, and/or heat shrinking to ensure a secure connection.

13.About power connector technology

Power connector technology is a type of technology used to connect electrical components to a power source. It is used in a variety of applications, including consumer electronics, industrial equipment, and automotive systems. Power connectors are designed to provide a secure connection between two components, while also allowing for easy disconnection. They are available in a variety of shapes and sizes, and can be used to connect components to a variety of power sources, including AC and DC power. Power connectors are typically made from metal or

14.How do you select the appropriate locking mechanism for a power connector?

1. Consider the application: The type of locking mechanism you choose should be based on the application and the environment in which the power connector will be used. For example, if the connector will be used in a harsh environment, you may want to choose a locking mechanism that is more robust and resistant to corrosion. 2. Consider the size: The size of the power connector should also be taken into account when selecting a locking mechanism. If the connector is too small, then a locking

15.Are power connectors standardized in terms of size and shape?

No, power connectors are not standardized in terms of size and shape. Different types of power connectors come in a variety of sizes and shapes, depending on the application.

16.What is the purpose of a power connector?

A power connector is used to connect a power source to an electrical device. It is used to provide power to the device and to protect the device from power surges.

17.How does impedance affect the performance of a power connector?

Impedance affects the performance of a power connector by limiting the amount of current that can flow through the connector. If the impedance is too high, the connector will not be able to handle the amount of current needed to power the device. If the impedance is too low, the connector will be overloaded and may cause damage to the device.

Tag:JYP Series power blade connector,JYF Series card edge connector,YRT Series