feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

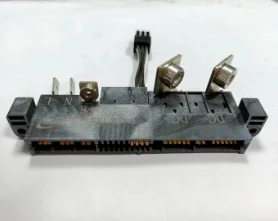

| Component Type | chassis power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 8 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.About chassis power connector overseas warehouse

Power connector overseas warehouses are warehouses located in foreign countries that store power connectors and related components. These warehouses are used to store and distribute power connectors to customers in different countries. They are typically located near major ports and airports, allowing for easy access to international customers. Power connector overseas warehouses are beneficial for companies that need to ship power connectors to customers in different countries quickly and efficiently.

2.What types of chassis power connectors are available in the market?

Our chassis power connector products undergo strict quality control to ensure customer satisfaction. 1. Molex Connectors 2. ATX Connectors 3. SATA Connectors 4. PCIe Connectors 5. 4-Pin Connectors 6. 6-Pin Connectors 7. 8-Pin Connectors 8. 10-Pin Connectors 9. 12-Pin Connectors 10. 24-Pin Connectors

3.How important is the overall quality of a chassis power connector?

Being one of the top chassis power connector manufacturers in China, We attach great importance to this detail. The overall quality of a power connector is very important. Poor quality connectors can cause electrical problems, such as shorts, arcing, and overheating, which can lead to equipment failure or even fire. High-quality connectors are designed to provide reliable, safe connections and are built to last.

4.Can chassis power connectors be used for both AC and DC power?

We have established a good reputation and reliable partnerships within the chassis power connector industry. No, power connectors are designed to be used for either AC or DC power, but not both.

5.Can chassis power connectors support high-frequency signals?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can support high-frequency signals. However, the type of connector used will depend on the specific application and the frequency of the signal. For example, coaxial connectors are often used for high-frequency signals, while screw terminals are better suited for lower-frequency signals.

6.Are there any options for waterproof or dustproof chassis power connectors?

As one of the top chassis power connector manufacturers in China, we take this very seriously. Yes, there are several options for waterproof and dustproof power connectors. These include IP67 rated connectors, which are designed to be waterproof and dustproof, as well as waterproof and dustproof cable glands, which are designed to protect cables from water and dust. Additionally, there are several types of waterproof and dustproof junction boxes, which are designed to protect electrical connections from water and dust.

7.About chassis power connector production skills training

Power connector production skills training is designed to help workers learn the skills needed to produce power connectors. This type of training typically covers topics such as the types of power connectors available, the tools and materials needed to produce them, and the steps involved in the production process. It may also include instruction on safety protocols and quality control measures. Training may be provided in a classroom setting or online.

8.Are there any color code standards for different chassis power connectors?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, there are color code standards for different power connectors. The most common color code standards are the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). The IEC color code standard is used for most European countries, while the NEMA color code standard is used in the United States.

9.Is there a maximum distance that a chassis power connector can cover?

chassis power connector is not a product only, but also can help you comes to money-making. The maximum distance that a power connector can cover depends on the type of connector and the power requirements of the device. Generally, the maximum distance for a power connector is determined by the voltage and current requirements of the device, as well as the type of cable used. For example, a USB cable can typically carry up to 5 volts and 1.5 amps over a distance of up to 5 meters (16 feet).

10.Can chassis power connectors be used in high vibration environments, such as in airplanes or trains?

Yes, power connectors can be used in high vibration environments, such as in airplanes or trains. However, it is important to use connectors that are designed to withstand the vibration and shock of the environment. Specialized connectors, such as those with locking mechanisms, are available to ensure a secure connection in these environments.

11.Are there any options for tool-less installation of chassis power connectors?

Yes, there are several options for tool-less installation of power connectors. These include push-in connectors, twist-lock connectors, and snap-in connectors. Push-in connectors are the most common type of tool-less power connector and are designed to be inserted into a power socket without the need for any tools. Twist-lock connectors are also available and are designed to be twisted into place. Finally, snap-in connectors are designed to be snapped into place without the need for any tools.

12.How do you ensure proper polarity when using a chassis power connector?

We continuously upgrade our skills and knowledge to adapt to changing chassis power connector market needs. 1. Check the polarity markings on the connector and the power source. 2. Make sure the positive and negative terminals are connected correctly. 3. Use the correct type of connector for the power source. 4. Use a multimeter to test the polarity of the connection. 5. Use a polarized connector to ensure proper polarity.

13.What are the main safety features of a chassis power connector?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Insulation: Power connectors should be insulated to prevent electric shock and short circuits. 2. Grounding: Power connectors should be grounded to protect against electric shock and reduce the risk of fire. 3. Overload Protection: Power connectors should be designed to prevent overloads and protect against damage to the device. 4. Overvoltage Protection: Power connectors should be designed to prevent overvoltage and protect against damage to the device. 5. Short Circuit Protection: Power connectors should be designed to prevent short circuits and protect against damage to the device. 6. Surge Protection: Power connectors should be designed to protect against power surges and protect against damage to the device.

Tag:atx 12v power connector 8-pin and 4-pin,6 pin vs 8 pin power connector,pci express 6+2-pin power connector,amiga power connector,led strip light power connector