feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

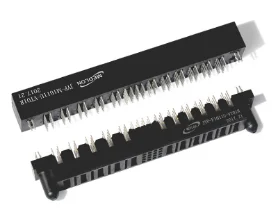

| Component Type | c8 power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 4 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.Are c8 power connectors standardized in terms of size and shape?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. No, power connectors are not standardized in terms of size and shape. Different types of power connectors come in a variety of sizes and shapes, depending on the application.

2.Can c8 power connectors be used in high vibration environments, such as in airplanes or trains?

Yes, power connectors can be used in high vibration environments, such as in airplanes or trains. However, it is important to use connectors that are designed to withstand the vibration and shock of the environment. Specialized connectors, such as those with locking mechanisms, are available to ensure a secure connection in these environments.

3.Can c8 power connectors be quickly and easily disconnected?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, power connectors can be quickly and easily disconnected. Many types of power connectors feature a quick-release mechanism that allows them to be disconnected with minimal effort.

4.How does the operating temperature range affect the performance of a c8 power connector?

The operating temperature range of a power connector affects its performance in several ways. Higher temperatures can cause the connector to become brittle and more prone to cracking or breaking. Higher temperatures can also cause the connector to expand, which can lead to poor contact between the connector and the mating part. Lower temperatures can cause the connector to become stiff and difficult to insert or remove. Additionally, lower temperatures can cause the connector to become brittle and more prone to cracking or breaking.

5.About c8 power connector MOQ

The MOQ for power connectors will depend on the type of connector and the supplier. Generally, the MOQ for power connectors is between 500 and 1000 pieces. However, some suppliers may offer lower MOQs depending on the type of connector and the quantity required.

6.What is the difference between a straight and a right-angle c8 power connector?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. A straight power connector is a type of connector that has two straight sides that are parallel to each other. This type of connector is typically used to connect two devices that are close together. A right-angle power connector is a type of connector that has two sides that are perpendicular to each other. This type of connector is typically used to connect two devices that are farther apart.

7.Can c8 power connectors be used for high-power applications?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can be used for high-power applications. However, it is important to select the right type of connector for the application, as some connectors are not designed to handle high power levels.

8.Can c8 power connectors be used for medical equipment?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Yes, power connectors can be used for medical equipment. However, it is important to ensure that the connectors are rated for medical use and meet the necessary safety standards.

9.Is there a risk of electrical shock when handling c8 power connectors?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, there is a risk of electrical shock when handling power connectors. It is important to make sure that all power connectors are properly insulated and that all safety precautions are taken when handling them.

10.How do you prevent the pins on a c8 power connector from getting damaged?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Inspect the pins for any damage before connecting the power connector. 2. Make sure the pins are aligned correctly before connecting the power connector. 3. Use a connector with a locking mechanism to ensure the pins stay in place. 4. Use a connector with a dust cover to protect the pins from dirt and debris. 5. Use a connector with a strain relief to reduce the stress on the pins. 6. Use a connector with a flexible cable to reduce the strain on the pins. 7. Use a connector with a protective sleeve to reduce the risk of pin damage. 8. Use a connector with a protective cap to reduce the risk of pin damage. 9. Use a connector with a protective shield to reduce the risk of pin damage. 10. Handle the connector with care to avoid any accidental damage to the pins.

11.How do you choose the right c8 power connector for a specific application?

We have established a good reputation and reliable partnerships within the c8 power connector industry. 1. Consider the current and voltage requirements of the application. 2. Determine the type of power connector that is compatible with the application. 3. Consider the environmental conditions in which the power connector will be used. 4. Consider the size and shape of the power connector. 5. Consider the cost of the power connector. 6. Consider the availability of the power connector. 7. Consider the safety features of the power connector.

12.About the development history of c8 power connector factory

The power connector factory was established in the early 1990s. It was founded by a group of experienced engineers and technicians who had been working in the connector industry for many years. The company has grown steadily over the years and has become one of the leading manufacturers of power connectors in the world. The company has developed a wide range of products, including power connectors, power cords, and power adapters. The company has also developed a range of custom solutions for customers, including custom-designed connectors and custom-made power cords. The company has also developed a range of innovative products, such as the Power Connector System, which is designed to provide a reliable and efficient connection between power sources and devices. The company has also developed a range of products for the automotive industry, including power connectors for cars, trucks, and motorcycles. The company has also developed a range of products for the medical industry, including power connectors for medical equipment.

13.Do c8 power connectors have a maximum number of mating cycles?

As one of the top c8 power connector manufacturers in China, we take this very seriously. Yes, power connectors typically have a maximum number of mating cycles. This number can vary depending on the type of connector and the manufacturer, but is typically between 500 and 1000 cycles.

14.About c8 power connector origin

The origin of power connectors can be traced back to the early days of electricity. In the late 19th century, the first electrical connectors were developed to connect electrical devices to power sources. These connectors were made of metal and were designed to be inserted into a socket. Over time, the design of power connectors has evolved to include a variety of shapes and sizes to accommodate different types of electrical devices. Today, power connectors are used in a wide range of applications, from consumer electronics to industrial machinery.

15.How do you ensure compatibility between a c8 power connector and the mating connector?

We operate our c8 power connector business with integrity and honesty. 1. Check the specifications of the power connector and the mating connector to ensure they are compatible. 2. Ensure the power connector and the mating connector have the same number of pins and the same pin spacing. 3. Ensure the power connector and the mating connector have the same voltage and current ratings. 4. Ensure the power connector and the mating connector have the same type of connector. 5. Ensure the power connector and the mating connector have the same type of insulation. 6. Ensure the power connector and the mating connector have the same type of contact material. 7. Ensure the power connector and the mating connector have the same type of mounting.

16.What is the expected lifespan of a c8 power connector?

We continuously upgrade our skills and knowledge to adapt to changing c8 power connector market needs. The expected lifespan of a power connector depends on the type of connector and the environment in which it is used. Generally, power connectors are designed to last for many years, but in some cases, they may need to be replaced after a few years of use.

Tag:rtx 4070 power connector,board to board power connector,8 pin 12 volt power connector