feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

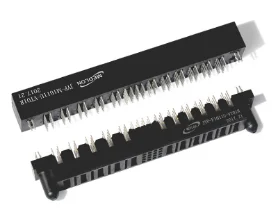

| Type: | c64 power connector | Packaging Details: | carton |

| Application: | Electric equipment | Supply Ability: | 10166 Piece/Pieces per Week |

| Place of Origin: | Chian,shenzhen | Port: | shenzhen |

| Brand Name: | Medlon | Quantity (pieces): | > 1001 |

| Model Number: | Customized options | Lead time (days): | To be negotiated |

| Contact barrel wire size: | 6-13AWG 13.3-3.3m㎡ | Feature: | makes assembly quick and easy |

| AVG contact resistance: | <247 | system: | Flat wiping contact system |

| Contact material: | Silver plated copper | Color: | Colored modular housings |

| Voltage rating: | 594V | Application: | Electric vehicles;Medical equipment;Power supply;Electric equipment |

| Rated current: | 56A | MOQ: | 30 |

1.Can c64 power connectors handle high voltages?

Being one of the top c64 power connector manufacturers in China, We attach great importance to this detail. No, power connectors are not designed to handle high voltages. High voltage applications require specialized connectors that are designed to safely handle the high voltage.

2.What is the maximum number of pins available for c64 power connectors?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. The maximum number of pins available for power connectors depends on the type of connector being used. For example, the ATX power connector used in most desktop computers has 24 pins, while the Molex connector used in many older computers has 4 pins.

3.About c64 power connector raw materials

Power connector raw materials are typically made from metals such as copper, aluminum, and brass. These metals are chosen for their electrical conductivity, strength, and corrosion resistance. Plastics such as polycarbonate, nylon, and ABS are also used in the construction of power connectors. These materials are chosen for their durability, flexibility, and insulation properties.

4.What is the purpose of a c64 power connector?

We operate our c64 power connector business with integrity and honesty. A power connector is used to connect a power source to an electrical device. It is used to provide power to the device and to protect the device from power surges.

5.What is a c64 power connector?

We focus on innovation and continuous improvement to maintain a competitive advantage. A power connector is a type of electrical connector used to connect a power supply to a device. It is typically used to provide power to electronic devices such as computers, printers, and other electronic equipment. Power connectors come in a variety of shapes and sizes, and are designed to fit specific power requirements.

6.About c64 power connector delivery date

The delivery date for power connectors will depend on the type of connector, the quantity, and the supplier. Generally, most suppliers will provide an estimated delivery date when the order is placed. If the order is urgent, some suppliers may be able to provide a faster delivery time.

7.What is the typical insertion and extraction force for a c64 power connector?

We continuously upgrade our skills and knowledge to adapt to changing c64 power connector market needs. The typical insertion and extraction force for a power connector will vary depending on the type of connector and the application. Generally, the insertion force should be between 0.5 and 2.5 pounds, while the extraction force should be between 0.5 and 5 pounds.

8.Can c64 power connectors handle power surges or fluctuations?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can handle power surges or fluctuations. However, it is important to use the correct type of power connector for the application. Some power connectors are designed to handle higher levels of power surges or fluctuations than others.

9.What is the expected lifespan of a c64 power connector?

We continuously upgrade our skills and knowledge to adapt to changing c64 power connector market needs. The expected lifespan of a power connector depends on the type of connector and the environment in which it is used. Generally, power connectors are designed to last for many years, but in some cases, they may need to be replaced after a few years of use.

10.Are there any environmentally-friendly options for c64 power connectors?

Our company has many years of c64 power connector experience and expertise. Yes, there are several environmentally-friendly options for power connectors. These include connectors made from recycled materials, connectors with low-impact manufacturing processes, and connectors with low-emission designs. Additionally, some connectors are designed to be more energy efficient, reducing the amount of energy used during operation.

11.Are there any options for PCB mount or panel mount c64 power connectors?

Yes, there are a variety of power connectors available for PCB mount and panel mount applications. These include Molex, JST, Phoenix, and Amphenol connectors.

12.Do c64 power connectors have a maximum number of mating cycles?

As one of the top c64 power connector manufacturers in China, we take this very seriously. Yes, power connectors typically have a maximum number of mating cycles. This number can vary depending on the type of connector and the manufacturer, but is typically between 500 and 1000 cycles.

13.About c64 power connector origin

The origin of power connectors can be traced back to the early days of electricity. In the late 19th century, the first electrical connectors were developed to connect electrical devices to power sources. These connectors were made of metal and were designed to be inserted into a socket. Over time, the design of power connectors has evolved to include a variety of shapes and sizes to accommodate different types of electrical devices. Today, power connectors are used in a wide range of applications, from consumer electronics to industrial machinery.

14.How important is proper grounding for c64 power connectors?

As one of the top c64 power connector manufacturers in China, we take this very seriously. Proper grounding for power connectors is extremely important. It helps to protect against electric shock, reduce interference, and ensure that the electrical system is functioning properly. Without proper grounding, the power connectors can become damaged or cause a fire hazard.

Tag:coaxial power connector female,8 pin video card power connector,gigabyte 3060 ti power connector,4-pin atx power connector,6 8 pin pcie power connector