feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

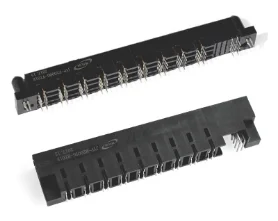

| Type: | blue power connector | Packaging Details: | carton |

| Application: | Electric equipment | Supply Ability: | 9911 Piece/Pieces per Week |

| Place of Origin: | Chian,shenzhen | Port: | shenzhen |

| Brand Name: | Medlon | Quantity (pieces): | > 999 |

| Model Number: | Customized options | Lead time (days): | To be negotiated |

| Contact barrel wire size: | 5-11AWG 13.3-3.3m㎡ | Feature: | makes assembly quick and easy |

| AVG contact resistance: | <140 | system: | Flat wiping contact system |

| Contact material: | Silver plated copper | Color: | Colored modular housings |

| Voltage rating: | 511V | Application: | Electric vehicles;Medical equipment;Power supply;Electric equipment |

| Rated current: | 55A | MOQ: | 30 |

1.Are there any options for tool-less installation of blue power connectors?

Yes, there are several options for tool-less installation of power connectors. These include push-in connectors, twist-lock connectors, and snap-in connectors. Push-in connectors are the most common type of tool-less power connector and are designed to be inserted into a power socket without the need for any tools. Twist-lock connectors are also available and are designed to be twisted into place. Finally, snap-in connectors are designed to be snapped into place without the need for any tools.

2.Are there any color code standards for different blue power connectors?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, there are color code standards for different power connectors. The most common color code standards are the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). The IEC color code standard is used for most European countries, while the NEMA color code standard is used in the United States.

3.What types of blue power connectors are available in the market?

Our blue power connector products undergo strict quality control to ensure customer satisfaction. 1. Molex Connectors 2. ATX Connectors 3. SATA Connectors 4. PCIe Connectors 5. 4-Pin Connectors 6. 6-Pin Connectors 7. 8-Pin Connectors 8. 10-Pin Connectors 9. 12-Pin Connectors 10. 24-Pin Connectors

4.Is there a risk of electrical shock when handling blue power connectors?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, there is a risk of electrical shock when handling power connectors. It is important to make sure that all power connectors are properly insulated and that all safety precautions are taken when handling them.

5.How do you choose the right blue power connector for a specific application?

We have established a good reputation and reliable partnerships within the blue power connector industry. 1. Consider the current and voltage requirements of the application. 2. Determine the type of power connector that is compatible with the application. 3. Consider the environmental conditions in which the power connector will be used. 4. Consider the size and shape of the power connector. 5. Consider the cost of the power connector. 6. Consider the availability of the power connector. 7. Consider the safety features of the power connector.

6.Can blue power connectors support high-frequency signals?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can support high-frequency signals. However, the type of connector used will depend on the specific application and the frequency of the signal. For example, coaxial connectors are often used for high-frequency signals, while screw terminals are better suited for lower-frequency signals.

7.About blue power connector raw material procurement system

The Power Connector Raw Material Procurement System is a software solution designed to streamline the procurement process for power connector raw materials. It provides a centralized platform for suppliers to submit bids, and for buyers to compare and select the best option. The system also includes features such as automated order tracking, inventory management, and supplier performance tracking. This system helps to reduce costs, improve efficiency, and ensure that the best quality materials are purchased.

8.About blue power connector production skills training

Power connector production skills training is designed to help workers learn the skills needed to produce power connectors. This type of training typically covers topics such as the types of power connectors available, the tools and materials needed to produce them, and the steps involved in the production process. It may also include instruction on safety protocols and quality control measures. Training may be provided in a classroom setting or online.

9.About blue power connector MOQ

The MOQ for power connectors will depend on the type of connector and the supplier. Generally, the MOQ for power connectors is between 500 and 1000 pieces. However, some suppliers may offer lower MOQs depending on the type of connector and the quantity required.

10.About the development history of blue power connector factory

The power connector factory was established in the early 1990s. It was founded by a group of experienced engineers and technicians who had been working in the connector industry for many years. The company has grown steadily over the years and has become one of the leading manufacturers of power connectors in the world. The company has developed a wide range of products, including power connectors, power cords, and power adapters. The company has also developed a range of custom solutions for customers, including custom-designed connectors and custom-made power cords. The company has also developed a range of innovative products, such as the Power Connector System, which is designed to provide a reliable and efficient connection between power sources and devices. The company has also developed a range of products for the automotive industry, including power connectors for cars, trucks, and motorcycles. The company has also developed a range of products for the medical industry, including power connectors for medical equipment.

11.About blue power connector raw materials

Power connector raw materials are typically made from metals such as copper, aluminum, and brass. These metals are chosen for their electrical conductivity, strength, and corrosion resistance. Plastics such as polycarbonate, nylon, and ABS are also used in the construction of power connectors. These materials are chosen for their durability, flexibility, and insulation properties.

12.How do you troubleshoot common issues with blue power connectors?

Being one of the top blue power connector manufacturers in China, We attach great importance to this detail. 1. Check the power source: Make sure the power source is working properly and is providing the correct voltage. 2. Check the power connector: Inspect the power connector for any signs of damage or corrosion. If the connector is damaged, replace it. 3. Check the wiring: Inspect the wiring for any signs of damage or corrosion. If the wiring is damaged, replace it. 4. Check the connection: Make sure the power connector is securely connected to the power source and the device. 5. Check the device: Make sure the device is working properly and is receiving the correct voltage. 6. Check the fuse: If the device is not receiving power, check the fuse to make sure it is not blown. If the fuse is blown, replace it.

13.How important is the overall quality of a blue power connector?

Being one of the top blue power connector manufacturers in China, We attach great importance to this detail. The overall quality of a power connector is very important. Poor quality connectors can cause electrical problems, such as shorts, arcing, and overheating, which can lead to equipment failure or even fire. High-quality connectors are designed to provide reliable, safe connections and are built to last.

14.What is the maximum number of pins available for blue power connectors?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. The maximum number of pins available for power connectors depends on the type of connector being used. For example, the ATX power connector used in most desktop computers has 24 pins, while the Molex connector used in many older computers has 4 pins.

15.How do you prevent the pins on a blue power connector from getting damaged?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Inspect the pins for any damage before connecting the power connector. 2. Make sure the pins are aligned correctly before connecting the power connector. 3. Use a connector with a locking mechanism to ensure the pins stay in place. 4. Use a connector with a dust cover to protect the pins from dirt and debris. 5. Use a connector with a strain relief to reduce the stress on the pins. 6. Use a connector with a flexible cable to reduce the strain on the pins. 7. Use a connector with a protective sleeve to reduce the risk of pin damage. 8. Use a connector with a protective cap to reduce the risk of pin damage. 9. Use a connector with a protective shield to reduce the risk of pin damage. 10. Handle the connector with care to avoid any accidental damage to the pins.

Tag:male dc power connector,12v power connector,4 pin male power connector,amphenol dc power connector