feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

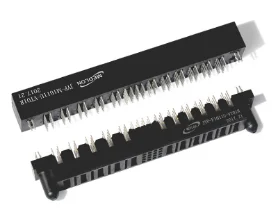

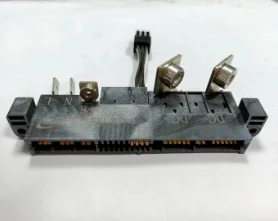

| Component Type | atx power connector definition |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 8 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.Are there any options for tool-less installation of atx power connector definitions?

Yes, there are several options for tool-less installation of power connectors. These include push-in connectors, twist-lock connectors, and snap-in connectors. Push-in connectors are the most common type of tool-less power connector and are designed to be inserted into a power socket without the need for any tools. Twist-lock connectors are also available and are designed to be twisted into place. Finally, snap-in connectors are designed to be snapped into place without the need for any tools.

2.What is the maximum temperature that a atx power connector definition can withstand?

We have established a good reputation and reliable partnerships within the atx power connector definition industry. The maximum temperature that a power connector can withstand depends on the type of connector and the materials used in its construction. Generally, power connectors are designed to withstand temperatures up to 125°C (257°F).

3.Do atx power connector definitions have a maximum number of mating cycles?

As one of the top atx power connector definition manufacturers in China, we take this very seriously. Yes, power connectors typically have a maximum number of mating cycles. This number can vary depending on the type of connector and the manufacturer, but is typically between 500 and 1000 cycles.

4.What is the typical insertion and extraction force for a atx power connector definition?

We continuously upgrade our skills and knowledge to adapt to changing atx power connector definition market needs. The typical insertion and extraction force for a power connector will vary depending on the type of connector and the application. Generally, the insertion force should be between 0.5 and 2.5 pounds, while the extraction force should be between 0.5 and 5 pounds.

5.Can atx power connector definitions be used in harsh environments?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can be used in harsh environments. Many power connectors are designed to be durable and resistant to extreme temperatures, dust, moisture, and other environmental factors.

6.About atx power connector definition production capacity

The production capacity of power connectors depends on the type of connector and the manufacturer. Generally, the production capacity of power connectors is determined by the number of machines and the number of workers available. The production capacity of a single machine is usually limited to a few thousand pieces per day. However, with the help of automation, the production capacity of a single machine can be increased to several hundred thousand pieces per day.

7.Are there any specific considerations when using atx power connector definitions for industrial applications?

As one of the atx power connector definition market leaders, we are known for innovation and reliability. Yes, there are several considerations when using power connectors for industrial applications. These include: 1. Ensuring the connectors are rated for the voltage and current requirements of the application. 2. Ensuring the connectors are rated for the environmental conditions of the application. 3. Ensuring the connectors are compatible with the mating connectors used in the application. 4. Ensuring the connectors are designed to meet the safety requirements of the application. 5. Ensuring the connectors are designed to meet the durability requirements of the application. 6. Ensuring the connectors are designed to meet the EMI/RFI requirements of the application.

8.How do you ensure compatibility between a atx power connector definition and the mating connector?

We operate our atx power connector definition business with integrity and honesty. 1. Check the specifications of the power connector and the mating connector to ensure they are compatible. 2. Ensure the power connector and the mating connector have the same number of pins and the same pin spacing. 3. Ensure the power connector and the mating connector have the same voltage and current ratings. 4. Ensure the power connector and the mating connector have the same type of connector. 5. Ensure the power connector and the mating connector have the same type of insulation. 6. Ensure the power connector and the mating connector have the same type of contact material. 7. Ensure the power connector and the mating connector have the same type of mounting.

9.What is the difference between a straight and a right-angle atx power connector definition?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. A straight power connector is a type of connector that has two straight sides that are parallel to each other. This type of connector is typically used to connect two devices that are close together. A right-angle power connector is a type of connector that has two sides that are perpendicular to each other. This type of connector is typically used to connect two devices that are farther apart.

10.Can atx power connector definitions be quickly and easily disconnected?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, power connectors can be quickly and easily disconnected. Many types of power connectors feature a quick-release mechanism that allows them to be disconnected with minimal effort.

11.About atx power connector definition warranty

Power connector warranties vary depending on the manufacturer. Generally, power connectors are covered by a limited warranty that covers defects in materials and workmanship for a specified period of time. The warranty period may range from one year to five years, depending on the manufacturer. Some manufacturers may also offer extended warranties for their power connectors. It is important to read the warranty information carefully before purchasing a power connector to ensure that it is covered by the warranty.

12.About atx power connector definition payment method

Power connector payment method is a payment system that allows customers to pay for goods and services using their mobile phones. It is a secure and convenient way to make payments, as customers can use their phones to make payments without having to enter their credit card information. The system is also designed to be fast and easy to use, allowing customers to make payments quickly and securely. Power connector payment method is becoming increasingly popular as more businesses are beginning to accept it as a payment option.

13.How does a atx power connector definition differ from a regular electrical connector?

Our mission is to provide customers with the best solutions for atx power connector definition. A power connector is designed to carry higher currents than a regular electrical connector. Power connectors are typically used to connect power supplies, motors, and other high-power devices. They are usually larger and sturdier than regular electrical connectors, and they often have additional safety features such as locking mechanisms and strain reliefs.

14.About atx power connector definition origin

The origin of power connectors can be traced back to the early days of electricity. In the late 19th century, the first electrical connectors were developed to connect electrical devices to power sources. These connectors were made of metal and were designed to be inserted into a socket. Over time, the design of power connectors has evolved to include a variety of shapes and sizes to accommodate different types of electrical devices. Today, power connectors are used in a wide range of applications, from consumer electronics to industrial machinery.

Tag:2x4 power connector,4090 fe power connector,power connector,floppy power connector,16-pin pcie 5.0 power connector