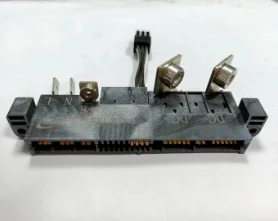

feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

| Type: | at&t fiber power connector | Packaging Details: | carton |

| Application: | Electric equipment | Supply Ability: | 10291 Piece/Pieces per Week |

| Place of Origin: | Chian,shenzhen | Port: | shenzhen |

| Brand Name: | Medlon | Quantity (pieces): | > 944 |

| Model Number: | Customized options | Lead time (days): | To be negotiated |

| Contact barrel wire size: | 6-11AWG 13.3-3.3m㎡ | Feature: | makes assembly quick and easy |

| AVG contact resistance: | <199 | system: | Flat wiping contact system |

| Contact material: | Silver plated copper | Color: | Colored modular housings |

| Voltage rating: | 540V | Application: | Electric vehicles;Medical equipment;Power supply;Electric equipment |

| Rated current: | 56A | MOQ: | 30 |

1.About at&t fiber power connector warranty

Power connector warranties vary depending on the manufacturer. Generally, power connectors are covered by a limited warranty that covers defects in materials and workmanship for a specified period of time. The warranty period may range from one year to five years, depending on the manufacturer. Some manufacturers may also offer extended warranties for their power connectors. It is important to read the warranty information carefully before purchasing a power connector to ensure that it is covered by the warranty.

2.About at&t fiber power connector patent

A power connector patent is a type of patent that covers the design and/or function of a power connector. This type of patent is typically used to protect the design of a power connector from being copied or used without permission. It can also be used to protect the function of a power connector, such as the way it connects to a power source or the way it transmits power. Power connector patents can be used to protect a wide range of products, from small electronic devices to large industrial machines.

3.What is the maximum number of pins available for at&t fiber power connectors?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. The maximum number of pins available for power connectors depends on the type of connector being used. For example, the ATX power connector used in most desktop computers has 24 pins, while the Molex connector used in many older computers has 4 pins.

4.Are there any special considerations when using at&t fiber power connectors in high altitude environments?

We are a professional at&t fiber power connector company dedicated to providing high quality products and services. Yes, there are several special considerations when using power connectors in high altitude environments. These include: using connectors with a higher current rating, using connectors with a higher voltage rating, using connectors with a higher temperature rating, using connectors with a higher insulation resistance rating, and using connectors with a higher dielectric strength rating. Additionally, it is important to ensure that the connectors are properly sealed to prevent moisture from entering the connection.

5.Are there any options for PCB mount or panel mount at&t fiber power connectors?

Yes, there are a variety of power connectors available for PCB mount and panel mount applications. These include Molex, JST, Phoenix, and Amphenol connectors.

6.About at&t fiber power connector production management system

The Power Connector Production Management System is a comprehensive system designed to help manufacturers manage the production of power connectors. It provides a comprehensive set of tools to help manufacturers track and manage the production process from start to finish. It includes features such as inventory tracking, order tracking, production scheduling, quality control, and cost analysis. The system also provides real-time data and analytics to help manufacturers make informed decisions about their production processes. Additionally, the system can be integrated with other systems such as ERP and CRM to provide a comprehensive view of the production process.

7.About at&t fiber power connector production skills training

Power connector production skills training is designed to help workers learn the skills needed to produce power connectors. This type of training typically covers topics such as the types of power connectors available, the tools and materials needed to produce them, and the steps involved in the production process. It may also include instruction on safety protocols and quality control measures. Training may be provided in a classroom setting or online.

8.Are there any special tools or techniques required for installing a at&t fiber power connector?

Our at&t fiber power connector products undergo strict quality control to ensure customer satisfaction. Yes, special tools and techniques are required for installing a power connector. Depending on the type of power connector, you may need a crimping tool, soldering iron, wire strippers, and/or heat shrink tubing. Additionally, you may need to use specific techniques such as soldering, crimping, and/or heat shrinking to ensure a secure connection.

9.How does the operating temperature range affect the performance of a at&t fiber power connector?

The operating temperature range of a power connector affects its performance in several ways. Higher temperatures can cause the connector to become brittle and more prone to cracking or breaking. Higher temperatures can also cause the connector to expand, which can lead to poor contact between the connector and the mating part. Lower temperatures can cause the connector to become stiff and difficult to insert or remove. Additionally, lower temperatures can cause the connector to become brittle and more prone to cracking or breaking.

10.What is the expected lifespan of a at&t fiber power connector?

We continuously upgrade our skills and knowledge to adapt to changing at&t fiber power connector market needs. The expected lifespan of a power connector depends on the type of connector and the environment in which it is used. Generally, power connectors are designed to last for many years, but in some cases, they may need to be replaced after a few years of use.

11.What kind of material is commonly used for making at&t fiber power connectors?

We focus on innovation and continuous improvement to maintain a competitive advantage. Power connectors are typically made from metals such as copper, aluminum, and brass, as well as plastics such as nylon and polycarbonate.

12.Are there any safety standards that at&t fiber power connectors have to meet?

We operate our at&t fiber power connector business with integrity and honesty. Yes, power connectors must meet safety standards set by the International Electrotechnical Commission (IEC). These standards cover a range of topics, including electrical safety, mechanical strength, environmental protection, and electromagnetic compatibility.

13.Is it possible to customize the design or length of a at&t fiber power connector?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Yes, it is possible to customize the design or length of a power connector. Many companies offer custom power connectors that can be designed to meet specific requirements. These custom connectors can be designed to fit a variety of applications and can be made in different lengths, shapes, and sizes.

14.About the development history of at&t fiber power connector factory

The power connector factory was established in the early 1990s. It was founded by a group of experienced engineers and technicians who had been working in the connector industry for many years. The company has grown steadily over the years and has become one of the leading manufacturers of power connectors in the world. The company has developed a wide range of products, including power connectors, power cords, and power adapters. The company has also developed a range of custom solutions for customers, including custom-designed connectors and custom-made power cords. The company has also developed a range of innovative products, such as the Power Connector System, which is designed to provide a reliable and efficient connection between power sources and devices. The company has also developed a range of products for the automotive industry, including power connectors for cars, trucks, and motorcycles. The company has also developed a range of products for the medical industry, including power connectors for medical equipment.

15.What are the advantages of using a at&t fiber power connector instead of a wire-to-wire connection?

Our products & services cover a wide range of areas and meet the needs of different fields. 1. Power connectors provide a secure and reliable connection that is less prone to accidental disconnection. 2. Power connectors are easier to install and require less time and effort than wire-to-wire connections. 3. Power connectors are more resistant to vibration and shock, making them more reliable in harsh environments. 4. Power connectors are more efficient at transferring power, reducing the risk of overheating and fire. 5. Power connectors are more cost-effective than wire-to-wire connections, as they require fewer components and less labor.

16.How does impedance affect the performance of a at&t fiber power connector?

As one of the at&t fiber power connector market leaders, we are known for innovation and reliability. Impedance affects the performance of a power connector by limiting the amount of current that can flow through the connector. If the impedance is too high, the connector will not be able to handle the amount of current needed to power the device. If the impedance is too low, the connector will be overloaded and may cause damage to the device.

Tag:1 x 6 pin power connector,pc motherboard power connector,power connector 3 pin,8 pin mobo power connector,1 x 24 pin atx main power connector