feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

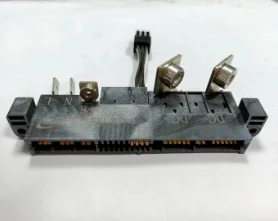

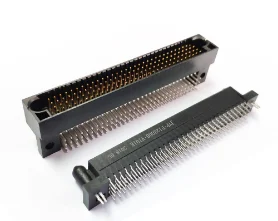

| Component Type | anderson 120a power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 5 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.About anderson 120a power connector raw materials

Power connector raw materials are typically made from metals such as copper, aluminum, and brass. These metals are chosen for their electrical conductivity, strength, and corrosion resistance. Plastics such as polycarbonate, nylon, and ABS are also used in the construction of power connectors. These materials are chosen for their durability, flexibility, and insulation properties.

2.What is the maximum temperature that a anderson 120a power connector can withstand?

We have established a good reputation and reliable partnerships within the anderson 120a power connector industry. The maximum temperature that a power connector can withstand depends on the type of connector and the materials used in its construction. Generally, power connectors are designed to withstand temperatures up to 125°C (257°F).

3.What are the main components of a anderson 120a power connector?

We are a professional anderson 120a power connector company dedicated to providing high quality products and services. The main components of a power connector are the housing, contacts, and strain relief. The housing is the outer shell of the connector that holds the contacts and strain relief in place. The contacts are the electrical terminals that make contact with the mating connector. The strain relief is a flexible material that helps to secure the cable to the connector and prevents it from being pulled out.

4.How do you ensure a secure and reliable connection with a anderson 120a power connector?

anderson 120a power connector is not a product only, but also can help you comes to money-making. 1. Use a connector with a locking mechanism to ensure a secure connection. 2. Inspect the connector and cable for any signs of damage or wear before connecting. 3. Use a connector with a high current rating to ensure it can handle the power requirements of the device. 4. Use a connector with a high voltage rating to ensure it can handle the voltage requirements of the device. 5. Use a connector with a high temperature rating to ensure it can handle the temperature requirements of the device. 6. Use a connector with a high dielectric strength rating to ensure it can handle the electrical requirements of the device. 7. Use a connector with a high insulation resistance rating to ensure it can handle the electrical requirements of the device. 8. Use a connector with a high contact resistance rating to ensure it can handle the electrical requirements of the device. 9. Use a connector with a high vibration resistance rating to ensure it can handle the mechanical requirements of the device. 10. Use a connector with a high shock resistance rating to ensure it can handle the mechanical requirements of the device.

5.Are anderson 120a power connectors standardized in terms of size and shape?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. No, power connectors are not standardized in terms of size and shape. Different types of power connectors come in a variety of sizes and shapes, depending on the application.

6.About anderson 120a power connector inventory

Power connector inventory is a type of inventory that is used to track the various types of power connectors that are used in a variety of electronic devices. This type of inventory is important for ensuring that the right type of power connector is available for any given device. It also helps to ensure that the correct type of power connector is used in the correct application. This type of inventory can be used to track the quantity of each type of power connector, as well as the type of connector and the manufacturer.

7.About anderson 120a power connector delivery date

The delivery date for power connectors will depend on the type of connector, the quantity, and the supplier. Generally, most suppliers will provide an estimated delivery date when the order is placed. If the order is urgent, some suppliers may be able to provide a faster delivery time.

8.About the development history of anderson 120a power connector factory

The power connector factory was established in the early 1990s. It was founded by a group of experienced engineers and technicians who had been working in the connector industry for many years. The company has grown steadily over the years and has become one of the leading manufacturers of power connectors in the world. The company has developed a wide range of products, including power connectors, power cords, and power adapters. The company has also developed a range of custom solutions for customers, including custom-designed connectors and custom-made power cords. The company has also developed a range of innovative products, such as the Power Connector System, which is designed to provide a reliable and efficient connection between power sources and devices. The company has also developed a range of products for the automotive industry, including power connectors for cars, trucks, and motorcycles. The company has also developed a range of products for the medical industry, including power connectors for medical equipment.

9.Can anderson 120a power connectors support high-frequency signals?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can support high-frequency signals. However, the type of connector used will depend on the specific application and the frequency of the signal. For example, coaxial connectors are often used for high-frequency signals, while screw terminals are better suited for lower-frequency signals.

10.Can anderson 120a power connectors handle high voltages?

Being one of the top anderson 120a power connector manufacturers in China, We attach great importance to this detail. No, power connectors are not designed to handle high voltages. High voltage applications require specialized connectors that are designed to safely handle the high voltage.

11.Can anderson 120a power connectors be used in low voltage applications?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Yes, power connectors can be used in low voltage applications. However, the power connector must be rated for the specific voltage and current requirements of the application.

12.Can anderson 120a power connectors be used for both AC and DC power?

We have established a good reputation and reliable partnerships within the anderson 120a power connector industry. No, power connectors are designed to be used for either AC or DC power, but not both.

13.Can anderson 120a power connectors be used for data transmission as well?

Our mission is to provide customers with the best solutions for anderson 120a power connector. No, power connectors are not designed for data transmission. They are designed to carry electrical power from one device to another. Data transmission requires a different type of connector, such as an Ethernet or USB connector.

14.Can anderson 120a power connectors be used in high vibration environments, such as in airplanes or trains?

Yes, power connectors can be used in high vibration environments, such as in airplanes or trains. However, it is important to use connectors that are designed to withstand the vibration and shock of the environment. Specialized connectors, such as those with locking mechanisms, are available to ensure a secure connection in these environments.

15.What is the purpose of a anderson 120a power connector?

We operate our anderson 120a power connector business with integrity and honesty. A power connector is used to connect a power source to an electrical device. It is used to provide power to the device and to protect the device from power surges.

Tag:cb radio power connector,970 power connector,bulgin power connector