feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

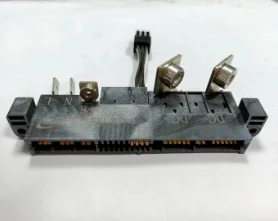

| Component Type | american power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 5 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.About american power connector raw materials

Power connector raw materials are typically made from metals such as copper, aluminum, and brass. These metals are chosen for their electrical conductivity, strength, and corrosion resistance. Plastics such as polycarbonate, nylon, and ABS are also used in the construction of power connectors. These materials are chosen for their durability, flexibility, and insulation properties.

2.About the development history of american power connector factory

The power connector factory was established in the early 1990s. It was founded by a group of experienced engineers and technicians who had been working in the connector industry for many years. The company has grown steadily over the years and has become one of the leading manufacturers of power connectors in the world. The company has developed a wide range of products, including power connectors, power cords, and power adapters. The company has also developed a range of custom solutions for customers, including custom-designed connectors and custom-made power cords. The company has also developed a range of innovative products, such as the Power Connector System, which is designed to provide a reliable and efficient connection between power sources and devices. The company has also developed a range of products for the automotive industry, including power connectors for cars, trucks, and motorcycles. The company has also developed a range of products for the medical industry, including power connectors for medical equipment.

3.Do american power connectors have a maximum number of mating cycles?

As one of the top american power connector manufacturers in China, we take this very seriously. Yes, power connectors typically have a maximum number of mating cycles. This number can vary depending on the type of connector and the manufacturer, but is typically between 500 and 1000 cycles.

4.About american power connector R&D capabilities

Power connector R&D capabilities vary from company to company. Some companies specialize in developing custom power connectors for specific applications, while others may have a more general focus on developing power connectors for a variety of applications. Companies may also specialize in developing power connectors for specific industries, such as automotive, medical, or industrial. Additionally, some companies may have the capability to develop power connectors with specific features, such as waterproofing or high-temperature resistance. Companies may also have the capability to develop power connectors with specific certifications, such as UL or CE.

5.About american power connector technology

Power connector technology is a type of technology used to connect electrical components to a power source. It is used in a variety of applications, including consumer electronics, industrial equipment, and automotive systems. Power connectors are designed to provide a secure connection between two components, while also allowing for easy disconnection. They are available in a variety of shapes and sizes, and can be used to connect components to a variety of power sources, including AC and DC power. Power connectors are typically made from metal or plastic, and are designed to be durable and reliable.

6.About american power connector origin

The origin of power connectors can be traced back to the early days of electricity. In the late 19th century, the first electrical connectors were developed to connect electrical devices to power sources. These connectors were made of metal and were designed to be inserted into a socket. Over time, the design of power connectors has evolved to include a variety of shapes and sizes to accommodate different types of electrical devices. Today, power connectors are used in a wide range of applications, from consumer electronics to industrial machinery.

7.Are there any options for waterproof or dustproof american power connectors?

As one of the top american power connector manufacturers in China, we take this very seriously. Yes, there are several options for waterproof and dustproof power connectors. These include IP67 rated connectors, which are designed to be waterproof and dustproof, as well as waterproof and dustproof cable glands, which are designed to protect cables from water and dust. Additionally, there are several types of waterproof and dustproof junction boxes, which are designed to protect electrical connections from water and dust.

8.What are the advantages of using a american power connector instead of a wire-to-wire connection?

Our products & services cover a wide range of areas and meet the needs of different fields. 1. Power connectors provide a secure and reliable connection that is less prone to accidental disconnection. 2. Power connectors are easier to install and require less time and effort than wire-to-wire connections. 3. Power connectors are more resistant to vibration and shock, making them more reliable in harsh environments. 4. Power connectors are more efficient at transferring power, reducing the risk of overheating and fire. 5. Power connectors are more cost-effective than wire-to-wire connections, as they require fewer components and less labor.

9.What kind of material is commonly used for making american power connectors?

We focus on innovation and continuous improvement to maintain a competitive advantage. Power connectors are typically made from metals such as copper, aluminum, and brass, as well as plastics such as nylon and polycarbonate.

10.Can american power connectors be used for medical equipment?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Yes, power connectors can be used for medical equipment. However, it is important to ensure that the connectors are rated for medical use and meet the necessary safety standards.

11.About american power connector overseas warehouse

Power connector overseas warehouses are warehouses located in foreign countries that store power connectors and related components. These warehouses are used to store and distribute power connectors to customers in different countries. They are typically located near major ports and airports, allowing for easy access to international customers. Power connector overseas warehouses are beneficial for companies that need to ship power connectors to customers in different countries quickly and efficiently.

12.Can american power connectors be used for both AC and DC power?

We have established a good reputation and reliable partnerships within the american power connector industry. No, power connectors are designed to be used for either AC or DC power, but not both.

13.What is a american power connector?

We focus on innovation and continuous improvement to maintain a competitive advantage. A power connector is a type of electrical connector used to connect a power supply to a device. It is typically used to provide power to electronic devices such as computers, printers, and other electronic equipment. Power connectors come in a variety of shapes and sizes, and are designed to fit specific power requirements.

14.Can american power connectors handle power surges or fluctuations?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can handle power surges or fluctuations. However, it is important to use the correct type of power connector for the application. Some power connectors are designed to handle higher levels of power surges or fluctuations than others.

15.Can american power connectors be used in high vibration environments, such as in airplanes or trains?

Yes, power connectors can be used in high vibration environments, such as in airplanes or trains. However, it is important to use connectors that are designed to withstand the vibration and shock of the environment. Specialized connectors, such as those with locking mechanisms, are available to ensure a secure connection in these environments.

Tag:2 x 4 pin atx 12v power connector,2080ti power connector,20 4 pin atx power connector,3090 power connector