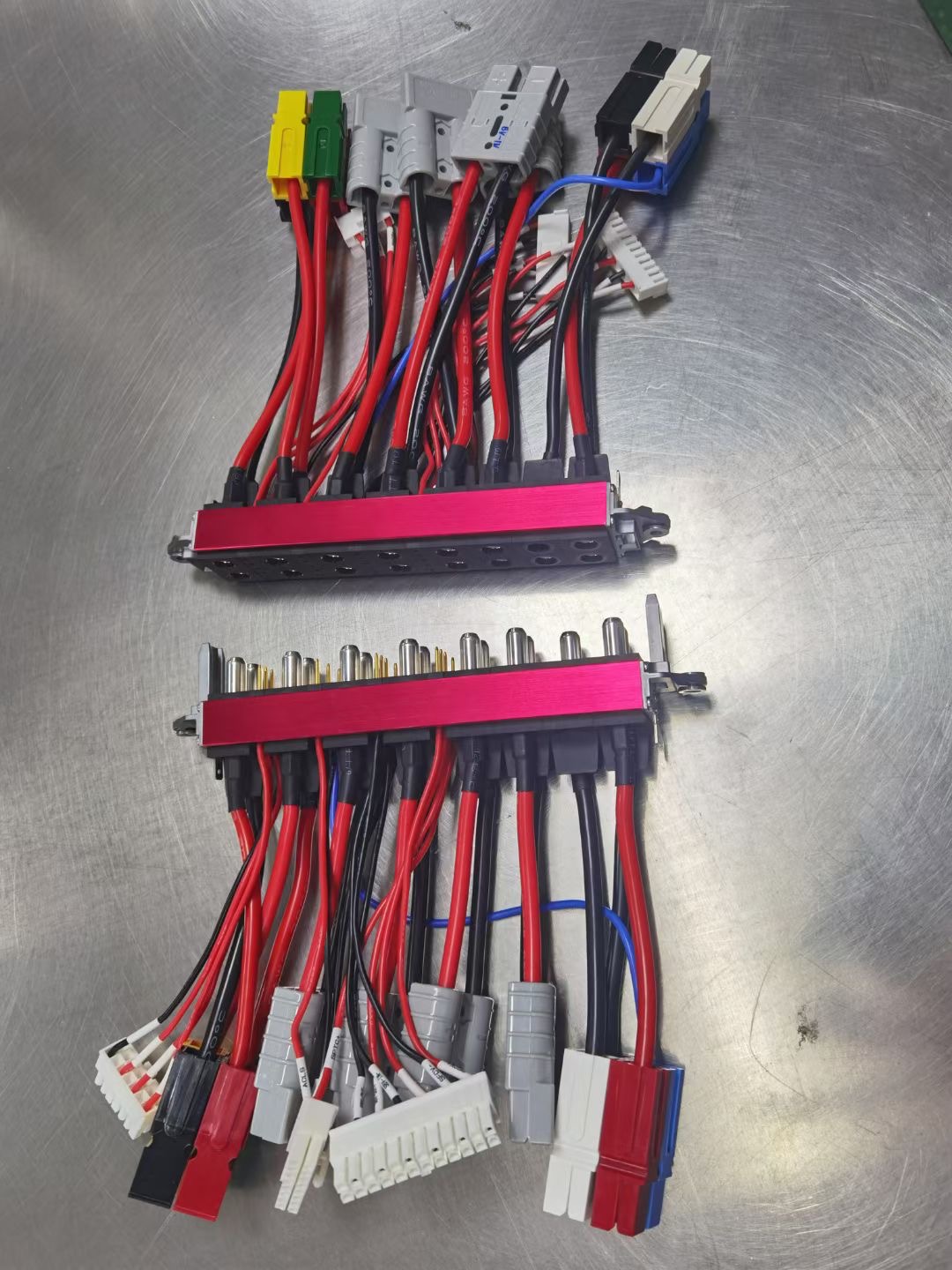

Industrial connectors: modular connectors's application: 1. New Energy Vehicles | Photovoltaic Energy Storage | Aerospace | Military Industry 2. Rail Transit ,Rail battery connector system| AGV | Automation | Testing and Measurement Applications 3. Floating device 4. Laboratory testing equipment and test benches, automatic production line equipment 5. robot 6. High voltage distribution 7. Commercial and household energy storage systems Female side specialty: High power terminal/Aluminum housing/Small and medium-sized power terminals/Calibration deviation/Up to 350A maximum/Guiding device Metal Pin specialty: Insulation resistance/High voltage terminal/Scalable features/Signal terminal/Automatic docking/Rubber core support block/Up to 5KV/High carrying capacity/Long service life/Minimum contact resistance/Anti vibration and impact resistance/Free configuration and expansion Modular industrial connector structure: Pin (male terminal);Aluminum Housing Module Connector

Same function with STAUBLI CombiTaC modular connectors

CombinConn modular connectors are widely used in the industrial field, and they can connect various types of connections, such as power supply

Signal, data, thermocouples, coaxial, fiber optic, pneumatic, and fluid are integrated into a compact frame or casing. C o m b i C o n n n connectors are multiple

Rational choice of function application, space saving, high current carrying capacity, long life cycle, can ensure that it is still available under the most severe mechanical and environmental conditions

Persistent and stable connection. C o m b i C o n n n can be applied to various machinery and equipment, including robots and experimental testing equipment, including the automotive manufacturing industry

And other industrial fields such as test benches, automatic generation equipment, and railway battery connection systems.

Application in the field of energy storage

The CombinConn modular connector is used to connect battery modules

Rack mounted solution connected to energy storage cabinet equipment

Durable and reliable connection

Adopting floating installation, it can automatically calibrate deviations

Ideal solution for high impact environments

Overall solution including cable components

Application in the field of automation

The CombinConn modular connector ensures that

Automatic production testing line runs continuously for a long time

With the increasing demand for efficiency and productivity in the automotive manufacturing industry, C om b i C o n n, with its sturdy, durable, and long-lasting connection characteristics, has become the best choice for durability and stability in harsh industrial environments.

C o m b i C o n n n can be applied to mechanical equipment, testing and measurement equipment, etc. in the automotive manufacturing industry, which can be achieved through a single modular connector system

Reliable and safe connection of power, signal, and data.

Test automation line test equipment

High end components ensure accurate testing results

Adopting floating installation, it can automatically calibrate deviations

Ideal solution for high impact environments

Up to 100000 times of plugging and unplugging

Reliable connection between the test bench and the tested automotive electronic equipment,

Ensure fast and safe connection and disconnection

Multi in one solution to save space

The maximum power can reach 300 A, 5 K V

Overall solution including cable components

Mechanical applications

High quality solutions for high-performance applications

Strong impact resistance and seismic resistance

Up to 100000 times of plugging and unplugging

CombinConn modular connector for host and

Main wiring connection between the main shaft heads of a multifunctional milling machine

With the increasing demand for functionality and modularity in modern manufacturing of large machinery, there is a need for a device that can simultaneously perform power, signal, and

A connector that can transmit data and achieve partial fast switching. CombiConn is very suitable for applications that require the quality and durability of connectors

Higher applications, such as tool quick change devices, automatic presses, packaging