feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

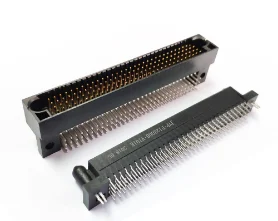

| Type: | 90 degree gpu power connector | Packaging Details: | carton |

| Application: | Electric equipment | Supply Ability: | 10415 Piece/Pieces per Week |

| Place of Origin: | Chian,shenzhen | Port: | shenzhen |

| Brand Name: | Medlon | Quantity (pieces): | > 945 |

| Model Number: | Customized options | Lead time (days): | To be negotiated |

| Contact barrel wire size: | 6-14AWG 13.3-3.3m㎡ | Feature: | makes assembly quick and easy |

| AVG contact resistance: | <115 | system: | Flat wiping contact system |

| Contact material: | Silver plated copper | Color: | Colored modular housings |

| Voltage rating: | 631V | Application: | Electric vehicles;Medical equipment;Power supply;Electric equipment |

| Rated current: | 43A | MOQ: | 30 |

1.Are there any options for waterproof or dustproof 90 degree gpu power connectors?

As one of the top 90 degree gpu power connector manufacturers in China, we take this very seriously. Yes, there are several options for waterproof and dustproof power connectors. These include IP67 rated connectors, which are designed to be waterproof and dustproof, as well as waterproof and dustproof cable glands, which are designed to protect cables from water and dust. Additionally, there are several types of waterproof and dustproof junction boxes, which are designed to protect electrical connections from water and dust.

2.Can a 90 degree gpu power connector handle high temperature and vibration?

Our mission is to provide customers with the best solutions for 90 degree gpu power connector. Yes, power connectors are designed to handle high temperatures and vibrations. They are typically made of materials such as stainless steel, aluminum, and brass, which are all resistant to high temperatures and vibrations.

3.How do you choose the right 90 degree gpu power connector for a specific application?

We have established a good reputation and reliable partnerships within the 90 degree gpu power connector industry. 1. Consider the current and voltage requirements of the application. 2. Determine the type of power connector that is compatible with the application. 3. Consider the environmental conditions in which the power connector will be used. 4. Consider the size and shape of the power connector. 5. Consider the cost of the power connector. 6. Consider the availability of the power connector. 7. Consider the safety features of the power connector.

4.What is the maximum temperature that a 90 degree gpu power connector can withstand?

We have established a good reputation and reliable partnerships within the 90 degree gpu power connector industry. The maximum temperature that a power connector can withstand depends on the type of connector and the materials used in its construction. Generally, power connectors are designed to withstand temperatures up to 125°C (257°F).

5.How do you ensure compatibility between a 90 degree gpu power connector and the mating connector?

We operate our 90 degree gpu power connector business with integrity and honesty. 1. Check the specifications of the power connector and the mating connector to ensure they are compatible. 2. Ensure the power connector and the mating connector have the same number of pins and the same pin spacing. 3. Ensure the power connector and the mating connector have the same voltage and current ratings. 4. Ensure the power connector and the mating connector have the same type of connector. 5. Ensure the power connector and the mating connector have the same type of insulation. 6. Ensure the power connector and the mating connector have the same type of contact material. 7. Ensure the power connector and the mating connector have the same type of mounting.

6.What is the typical voltage and current rating for 90 degree gpu power connectors?

90 degree gpu power connector is not a product only, but also can help you comes to money-making. The typical voltage and current rating for power connectors depends on the type of connector being used. For example, a standard IEC 60320 C13 connector is rated for 10A at 250V.

7.Are there any special considerations when using 90 degree gpu power connectors in high altitude environments?

We are a professional 90 degree gpu power connector company dedicated to providing high quality products and services. Yes, there are several special considerations when using power connectors in high altitude environments. These include: using connectors with a higher current rating, using connectors with a higher voltage rating, using connectors with a higher temperature rating, using connectors with a higher insulation resistance rating, and using connectors with a higher dielectric strength rating. Additionally, it is important to ensure that the connectors are properly sealed to prevent moisture from entering the connection.

8.How do you ensure proper insulation and protection against electrical hazards when using a 90 degree gpu power connector?

1. Use the correct type of power connector for the application. 2. Inspect the power connector for any signs of damage before use. 3. Ensure that the power connector is properly rated for the voltage and current of the application. 4. Use a surge protector or other protective device to protect against electrical surges. 5. Use a ground fault circuit interrupter (GFCI) to protect against electrical shock. 6. Use a power cord with a strain relief to prevent the power connector from becoming loose. 7. Use a power connector with a built-in fuse or circuit breaker to protect against overloads. 8. Make sure the power connector is properly secured to the device or outlet. 9. Use a power connector with a built-in insulation sleeve to protect against electrical hazards.

9.Can 90 degree gpu power connectors be used for both AC and DC power?

We have established a good reputation and reliable partnerships within the 90 degree gpu power connector industry. No, power connectors are designed to be used for either AC or DC power, but not both.

10.About 90 degree gpu power connector origin

The origin of power connectors can be traced back to the early days of electricity. In the late 19th century, the first electrical connectors were developed to connect electrical devices to power sources. These connectors were made of metal and were designed to be inserted into a socket. Over time, the design of power connectors has evolved to include a variety of shapes and sizes to accommodate different types of electrical devices. Today, power connectors are used in a wide range of applications, from consumer electronics to industrial machinery.

11.About 90 degree gpu power connector technology

Power connector technology is a type of technology used to connect electrical components to a power source. It is used in a variety of applications, including consumer electronics, industrial equipment, and automotive systems. Power connectors are designed to provide a secure connection between two components, while also allowing for easy disconnection. They are available in a variety of shapes and sizes, and can be used to connect components to a variety of power sources, including AC and DC power. Power connectors are typically made from metal or plastic, and are designed to be durable and reliable.

12.About 90 degree gpu power connector warranty

Power connector warranties vary depending on the manufacturer. Generally, power connectors are covered by a limited warranty that covers defects in materials and workmanship for a specified period of time. The warranty period may range from one year to five years, depending on the manufacturer. Some manufacturers may also offer extended warranties for their power connectors. It is important to read the warranty information carefully before purchasing a power connector to ensure that it is covered by the warranty.

13.Are there any color code standards for different 90 degree gpu power connectors?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, there are color code standards for different power connectors. The most common color code standards are the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). The IEC color code standard is used for most European countries, while the NEMA color code standard is used in the United States.

14.How do you ensure proper polarity when using a 90 degree gpu power connector?

We continuously upgrade our skills and knowledge to adapt to changing 90 degree gpu power connector market needs. 1. Check the polarity markings on the connector and the power source. 2. Make sure the positive and negative terminals are connected correctly. 3. Use the correct type of connector for the power source. 4. Use a multimeter to test the polarity of the connection. 5. Use a polarized connector to ensure proper polarity.

15.How do you determine the appropriate wire gauge for a 90 degree gpu power connector?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. The appropriate wire gauge for a power connector is determined by the current rating of the connector. The current rating is usually printed on the connector itself, and the wire gauge should be chosen to ensure that the current rating is not exceeded. The National Electrical Code (NEC) provides tables that list the maximum current rating for different wire gauges.

16.Are there any security features available for 90 degree gpu power connectors?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, there are several security features available for power connectors. These include locking mechanisms, tamper-proof seals, and keyed connectors. Additionally, some power connectors are designed with built-in surge protection to help protect against power surges.

Tag:atx motherboard power connector,4 pin power connector pc,1 x 24 pin atx main power connector,macbook power connector