feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

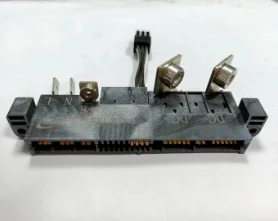

| Component Type | 8-pin pcie power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 9 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.Can 8-pin pcie power connectors be used in low voltage applications?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Yes, power connectors can be used in low voltage applications. However, the power connector must be rated for the specific voltage and current requirements of the application.

2.Can 8-pin pcie power connectors be quickly and easily disconnected?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, power connectors can be quickly and easily disconnected. Many types of power connectors feature a quick-release mechanism that allows them to be disconnected with minimal effort.

3.How do you prevent the pins on a 8-pin pcie power connector from getting damaged?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Inspect the pins for any damage before connecting the power connector. 2. Make sure the pins are aligned correctly before connecting the power connector. 3. Use a connector with a locking mechanism to ensure the pins stay in place. 4. Use a connector with a dust cover to protect the pins from dirt and debris. 5. Use a connector with a strain relief to reduce the stress on the pins. 6. Use a connector with a flexible cable to reduce the strain on the pins. 7. Use a connector with a protective sleeve to reduce the risk of pin damage. 8. Use a connector with a protective cap to reduce the risk of pin damage. 9. Use a connector with a protective shield to reduce the risk of pin damage. 10. Handle the connector with care to avoid any accidental damage to the pins.

4.Can 8-pin pcie power connectors support high-frequency signals?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can support high-frequency signals. However, the type of connector used will depend on the specific application and the frequency of the signal. For example, coaxial connectors are often used for high-frequency signals, while screw terminals are better suited for lower-frequency signals.

5.Can 8-pin pcie power connectors be used for high-power applications?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can be used for high-power applications. However, it is important to select the right type of connector for the application, as some connectors are not designed to handle high power levels.

6.About 8-pin pcie power connector R&D capabilities

Power connector R&D capabilities vary from company to company. Some companies specialize in developing custom power connectors for specific applications, while others may have a more general focus on developing power connectors for a variety of applications. Companies may also specialize in developing power connectors for specific industries, such as automotive, medical, or industrial. Additionally, some companies may have the capability to develop power connectors with specific features, such as waterproofing or high-temperature resistance. Companies may also have the capability to develop power connectors with specific certifications, such as UL or CE.

7.About 8-pin pcie power connector production capacity

The production capacity of power connectors depends on the type of connector and the manufacturer. Generally, the production capacity of power connectors is determined by the number of machines and the number of workers available. The production capacity of a single machine is usually limited to a few thousand pieces per day. However, with the help of automation, the production capacity of a single machine can be increased to several hundred thousand pieces per day.

8.How do you troubleshoot common issues with 8-pin pcie power connectors?

Being one of the top 8-pin pcie power connector manufacturers in China, We attach great importance to this detail. 1. Check the power source: Make sure the power source is working properly and is providing the correct voltage. 2. Check the power connector: Inspect the power connector for any signs of damage or corrosion. If the connector is damaged, replace it. 3. Check the wiring: Inspect the wiring for any signs of damage or corrosion. If the wiring is damaged, replace it. 4. Check the connection: Make sure the power connector is securely connected to the power source and the device. 5. Check the device: Make sure the device is working properly and is receiving the correct voltage. 6. Check the fuse: If the device is not receiving power, check the fuse to make sure it is not blown. If the fuse is blown, replace it.

9.Can 8-pin pcie power connectors be used in harsh environments?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can be used in harsh environments. Many power connectors are designed to be durable and resistant to extreme temperatures, dust, moisture, and other environmental factors.

10.How do you ensure proper insulation and protection against electrical hazards when using a 8-pin pcie power connector?

1. Use the correct type of power connector for the application. 2. Inspect the power connector for any signs of damage before use. 3. Ensure that the power connector is properly rated for the voltage and current of the application. 4. Use a surge protector or other protective device to protect against electrical surges. 5. Use a ground fault circuit interrupter (GFCI) to protect against electrical shock. 6. Use a power cord with a strain relief to prevent the power connector from becoming loose. 7. Use a power connector with a built-in fuse or circuit breaker to protect against overloads. 8. Make sure the power connector is properly secured to the device or outlet. 9. Use a power connector with a built-in insulation sleeve to protect against electrical hazards.

11.Can a 8-pin pcie power connector handle high temperature and vibration?

Our mission is to provide customers with the best solutions for 8-pin pcie power connector. Yes, power connectors are designed to handle high temperatures and vibrations. They are typically made of materials such as stainless steel, aluminum, and brass, which are all resistant to high temperatures and vibrations.

12.Is there a specific sequence for connecting and disconnecting a 8-pin pcie power connector?

As one of the 8-pin pcie power connector market leaders, we are known for innovation and reliability. Yes, there is a specific sequence for connecting and disconnecting a power connector. The sequence is as follows: 1. Disconnect the power source from the device. 2. Disconnect the power connector from the device. 3. Inspect the power connector for any damage or corrosion. 4. Connect the power connector to the device. 5. Reconnect the power source to the device. 6. Test the device to ensure proper operation.

13.About 8-pin pcie power connector payment method

Power connector payment method is a payment system that allows customers to pay for goods and services using their mobile phones. It is a secure and convenient way to make payments, as customers can use their phones to make payments without having to enter their credit card information. The system is also designed to be fast and easy to use, allowing customers to make payments quickly and securely. Power connector payment method is becoming increasingly popular as more businesses are beginning to accept it as a payment option.

14.Are there any color code standards for different 8-pin pcie power connectors?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, there are color code standards for different power connectors. The most common color code standards are the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). The IEC color code standard is used for most European countries, while the NEMA color code standard is used in the United States.

15.What is the typical voltage and current rating for 8-pin pcie power connectors?

8-pin pcie power connector is not a product only, but also can help you comes to money-making. The typical voltage and current rating for power connectors depends on the type of connector being used. For example, a standard IEC 60320 C13 connector is rated for 10A at 250V.

16.What is the expected lifespan of a 8-pin pcie power connector?

We continuously upgrade our skills and knowledge to adapt to changing 8-pin pcie power connector market needs. The expected lifespan of a power connector depends on the type of connector and the environment in which it is used. Generally, power connectors are designed to last for many years, but in some cases, they may need to be replaced after a few years of use.

Tag:3070 fe power connector,atx 12v power connector motherboard,1 x 8 pin 12v power connector