feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

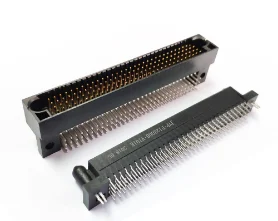

| Component Type | 6 pin and 8 pin power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 9 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.Can 6 pin and 8 pin power connectors be used for data transmission as well?

Our mission is to provide customers with the best solutions for 6 pin and 8 pin power connector. No, power connectors are not designed for data transmission. They are designed to carry electrical power from one device to another. Data transmission requires a different type of connector, such as an Ethernet or USB connector.

2.Are there any color code standards for different 6 pin and 8 pin power connectors?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, there are color code standards for different power connectors. The most common color code standards are the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). The IEC color code standard is used for most European countries, while the NEMA color code standard is used in the United States.

3.How do you troubleshoot common issues with 6 pin and 8 pin power connectors?

Being one of the top 6 pin and 8 pin power connector manufacturers in China, We attach great importance to this detail. 1. Check the power source: Make sure the power source is working properly and is providing the correct voltage. 2. Check the power connector: Inspect the power connector for any signs of damage or corrosion. If the connector is damaged, replace it. 3. Check the wiring: Inspect the wiring for any signs of damage or corrosion. If the wiring is damaged, replace it. 4. Check the connection: Make sure the power connector is securely connected to the power source and the device. 5. Check the device: Make sure the device is working properly and is receiving the correct voltage. 6. Check the fuse: If the device is not receiving power, check the fuse to make sure it is not blown. If the fuse is blown, replace it.

4.About 6 pin and 8 pin power connector quality system

A power connector quality system is a set of processes and procedures that are used to ensure the quality of power connectors. This system includes the design, manufacture, testing, and maintenance of power connectors. It also includes the inspection and certification of power connectors to ensure they meet the required standards. The system also includes the tracking and monitoring of power connector performance over time. The system should also include the development of corrective action plans to address any issues that arise.

5.How important is proper grounding for 6 pin and 8 pin power connectors?

As one of the top 6 pin and 8 pin power connector manufacturers in China, we take this very seriously. Proper grounding for power connectors is extremely important. It helps to protect against electric shock, reduce interference, and ensure that the electrical system is functioning properly. Without proper grounding, the power connectors can become damaged or cause a fire hazard.

6.How do you choose the right 6 pin and 8 pin power connector for a specific application?

We have established a good reputation and reliable partnerships within the 6 pin and 8 pin power connector industry. 1. Consider the current and voltage requirements of the application. 2. Determine the type of power connector that is compatible with the application. 3. Consider the environmental conditions in which the power connector will be used. 4. Consider the size and shape of the power connector. 5. Consider the cost of the power connector. 6. Consider the availability of the power connector. 7. Consider the safety features of the power connector.

7.How does the operating temperature range affect the performance of a 6 pin and 8 pin power connector?

The operating temperature range of a power connector affects its performance in several ways. Higher temperatures can cause the connector to become brittle and more prone to cracking or breaking. Higher temperatures can also cause the connector to expand, which can lead to poor contact between the connector and the mating part. Lower temperatures can cause the connector to become stiff and difficult to insert or remove. Additionally, lower temperatures can cause the connector to become brittle and more prone to cracking or breaking.

8.About 6 pin and 8 pin power connector production equipment

Power connector production equipment is used to manufacture power connectors for a variety of applications. This equipment is used to create a variety of power connectors, including those used in automotive, industrial, and consumer electronics. The equipment typically includes a variety of machines, such as presses, injection molding machines, and die-casting machines. The machines are used to create the various components of the power connectors, such as the contacts, housings, and terminals. The equipment is also used to assemble the components into the finished product.

9.How do you ensure proper insulation and protection against electrical hazards when using a 6 pin and 8 pin power connector?

1. Use the correct type of power connector for the application. 2. Inspect the power connector for any signs of damage before use. 3. Ensure that the power connector is properly rated for the voltage and current of the application. 4. Use a surge protector or other protective device to protect against electrical surges. 5. Use a ground fault circuit interrupter (GFCI) to protect against electrical shock. 6. Use a power cord with a strain relief to prevent the power connector from becoming loose. 7. Use a power connector with a built-in fuse or circuit breaker to protect against overloads. 8. Make sure the power connector is properly secured to the device or outlet. 9. Use a power connector with a built-in insulation sleeve to protect against electrical hazards.

10.About the development history of 6 pin and 8 pin power connector factory

The power connector factory was established in the early 1990s. It was founded by a group of experienced engineers and technicians who had been working in the connector industry for many years. The company has grown steadily over the years and has become one of the leading manufacturers of power connectors in the world. The company has developed a wide range of products, including power connectors, power cords, and power adapters. The company has also developed a range of custom solutions for customers, including custom-designed connectors and custom-made power cords. The company has also developed a range of innovative products, such as the Power Connector System, which is designed to provide a reliable and efficient connection between power sources and devices. The company has also developed a range of products for the automotive industry, including power connectors for cars, trucks, and motorcycles. The company has also developed a range of products for the medical industry, including power connectors for medical equipment.

11.About 6 pin and 8 pin power connector warranty

Power connector warranties vary depending on the manufacturer. Generally, power connectors are covered by a limited warranty that covers defects in materials and workmanship for a specified period of time. The warranty period may range from one year to five years, depending on the manufacturer. Some manufacturers may also offer extended warranties for their power connectors. It is important to read the warranty information carefully before purchasing a power connector to ensure that it is covered by the warranty.

12.What is the typical voltage and current rating for 6 pin and 8 pin power connectors?

6 pin and 8 pin power connector is not a product only, but also can help you comes to money-making. The typical voltage and current rating for power connectors depends on the type of connector being used. For example, a standard IEC 60320 C13 connector is rated for 10A at 250V.

13.What is a 6 pin and 8 pin power connector?

We focus on innovation and continuous improvement to maintain a competitive advantage. A power connector is a type of electrical connector used to connect a power supply to a device. It is typically used to provide power to electronic devices such as computers, printers, and other electronic equipment. Power connectors come in a variety of shapes and sizes, and are designed to fit specific power requirements.

14.About 6 pin and 8 pin power connector customization services

Power connector customization services are available from a variety of companies. These services allow customers to design and order custom power connectors that meet their specific needs. Companies that offer these services typically provide a wide range of options, including different sizes, shapes, and materials. Customers can also choose from a variety of colors and finishes. The customization process typically involves providing the company with detailed specifications, such as the type of connector, the number of pins, and the desired voltage and current ratings. The company then designs and manufactures the connector according to the customer’s specifications. Once the connector is complete, it is shipped to the customer for installation.

Tag:2080 ti power connector,4 4 pin power connector,2-pin power connector