feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

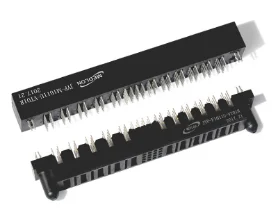

| Component Type | 6 2 power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 4 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.Are there any options for tool-less installation of 6 2 power connectors?

Yes, there are several options for tool-less installation of power connectors. These include push-in connectors, twist-lock connectors, and snap-in connectors. Push-in connectors are the most common type of tool-less power connector and are designed to be inserted into a power socket without the need for any tools. Twist-lock connectors are also available and are designed to be twisted into place. Finally, snap-in connectors are designed to be snapped into place without the need for any tools.

2.How important is the overall quality of a 6 2 power connector?

Being one of the top 6 2 power connector manufacturers in China, We attach great importance to this detail. The overall quality of a power connector is very important. Poor quality connectors can cause electrical problems, such as shorts, arcing, and overheating, which can lead to equipment failure or even fire. High-quality connectors are designed to provide reliable, safe connections and are built to last.

3.About 6 2 power connector raw materials

Power connector raw materials are typically made from metals such as copper, aluminum, and brass. These metals are chosen for their electrical conductivity, strength, and corrosion resistance. Plastics such as polycarbonate, nylon, and ABS are also used in the construction of power connectors. These materials are chosen for their durability, flexibility, and insulation properties.

4.What is the typical insertion and extraction force for a 6 2 power connector?

We continuously upgrade our skills and knowledge to adapt to changing 6 2 power connector market needs. The typical insertion and extraction force for a power connector will vary depending on the type of connector and the application. Generally, the insertion force should be between 0.5 and 2.5 pounds, while the extraction force should be between 0.5 and 5 pounds.

5.How does impedance affect the performance of a 6 2 power connector?

As one of the 6 2 power connector market leaders, we are known for innovation and reliability. Impedance affects the performance of a power connector by limiting the amount of current that can flow through the connector. If the impedance is too high, the connector will not be able to handle the amount of current needed to power the device. If the impedance is too low, the connector will be overloaded and may cause damage to the device.

6.How do you identify the proper orientation for a 6 2 power connector?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. The proper orientation for a power connector can be identified by looking at the shape of the connector and the corresponding port. The shape of the connector should match the shape of the port, and the pins should line up with the holes in the port. Additionally, the connector should have a notch or other indicator that shows which side should be facing up.

7.What is the maximum number of pins available for 6 2 power connectors?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. The maximum number of pins available for power connectors depends on the type of connector being used. For example, the ATX power connector used in most desktop computers has 24 pins, while the Molex connector used in many older computers has 4 pins.

8.Are there any environmentally-friendly options for 6 2 power connectors?

Our company has many years of 6 2 power connector experience and expertise. Yes, there are several environmentally-friendly options for power connectors. These include connectors made from recycled materials, connectors with low-impact manufacturing processes, and connectors with low-emission designs. Additionally, some connectors are designed to be more energy efficient, reducing the amount of energy used during operation.

9.Is there a risk of electrical shock when handling 6 2 power connectors?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, there is a risk of electrical shock when handling power connectors. It is important to make sure that all power connectors are properly insulated and that all safety precautions are taken when handling them.

10.How do you determine the appropriate wire gauge for a 6 2 power connector?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. The appropriate wire gauge for a power connector is determined by the current rating of the connector. The current rating is usually printed on the connector itself, and the wire gauge should be chosen to ensure that the current rating is not exceeded. The National Electrical Code (NEC) provides tables that list the maximum current rating for different wire gauges.

11.Does the size and configuration of a 6 2 power connector affect its performance?

We are a professional 6 2 power connector company dedicated to providing high quality products and services. Yes, the size and configuration of a power connector can affect its performance. The size of the connector determines the amount of current it can handle, and the configuration of the connector affects the amount of power it can deliver. For example, a larger connector can handle more current than a smaller one, and a connector with more pins can deliver more power than one with fewer pins.

12.About 6 2 power connector production management system

The Power Connector Production Management System is a comprehensive system designed to help manufacturers manage the production of power connectors. It provides a comprehensive set of tools to help manufacturers track and manage the production process from start to finish. It includes features such as inventory tracking, order tracking, production scheduling, quality control, and cost analysis. The system also provides real-time data and analytics to help manufacturers make informed decisions about their production processes. Additionally, the system can be integrated with other systems such as ERP and CRM to provide a comprehensive view of the production process.

13.Is it possible to customize the design or length of a 6 2 power connector?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Yes, it is possible to customize the design or length of a power connector. Many companies offer custom power connectors that can be designed to meet specific requirements. These custom connectors can be designed to fit a variety of applications and can be made in different lengths, shapes, and sizes.

14.What is the expected lifespan of a 6 2 power connector?

We continuously upgrade our skills and knowledge to adapt to changing 6 2 power connector market needs. The expected lifespan of a power connector depends on the type of connector and the environment in which it is used. Generally, power connectors are designed to last for many years, but in some cases, they may need to be replaced after a few years of use.

15.Can 6 2 power connectors be used for high-power applications?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can be used for high-power applications. However, it is important to select the right type of connector for the application, as some connectors are not designed to handle high power levels.

16.About 6 2 power connector production skills training

Power connector production skills training is designed to help workers learn the skills needed to produce power connectors. This type of training typically covers topics such as the types of power connectors available, the tools and materials needed to produce them, and the steps involved in the production process. It may also include instruction on safety protocols and quality control measures. Training may be provided in a classroom setting or online.

Tag:nest power connector no c terminal,4 pin fan power connector,12v dc power connector,rtx 3060 ti power connector