feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

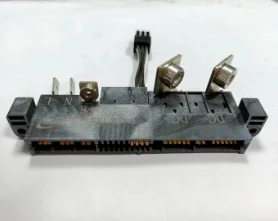

| Type: | 40 series power connector | Packaging Details: | carton |

| Application: | Electric equipment | Supply Ability: | 10347 Piece/Pieces per Week |

| Place of Origin: | Chian,shenzhen | Port: | shenzhen |

| Brand Name: | Medlon | Quantity (pieces): | > 917 |

| Model Number: | Customized options | Lead time (days): | To be negotiated |

| Contact barrel wire size: | 5-15AWG 13.3-3.3m㎡ | Feature: | makes assembly quick and easy |

| AVG contact resistance: | <119 | system: | Flat wiping contact system |

| Contact material: | Silver plated copper | Color: | Colored modular housings |

| Voltage rating: | 507V | Application: | Electric vehicles;Medical equipment;Power supply;Electric equipment |

| Rated current: | 51A | MOQ: | 30 |

1.What is the typical insertion and extraction force for a 40 series power connector?

We continuously upgrade our skills and knowledge to adapt to changing 40 series power connector market needs. The typical insertion and extraction force for a power connector will vary depending on the type of connector and the application. Generally, the insertion force should be between 0.5 and 2.5 pounds, while the extraction force should be between 0.5 and 5 pounds.

2.How does a 40 series power connector differ from a regular electrical connector?

Our mission is to provide customers with the best solutions for 40 series power connector. A power connector is designed to carry higher currents than a regular electrical connector. Power connectors are typically used to connect power supplies, motors, and other high-power devices. They are usually larger and sturdier than regular electrical connectors, and they often have additional safety features such as locking mechanisms and strain reliefs.

3.Can a 40 series power connector handle high temperature and vibration?

Our mission is to provide customers with the best solutions for 40 series power connector. Yes, power connectors are designed to handle high temperatures and vibrations. They are typically made of materials such as stainless steel, aluminum, and brass, which are all resistant to high temperatures and vibrations.

4.About 40 series power connector quality system

A power connector quality system is a set of processes and procedures that are used to ensure the quality of power connectors. This system includes the design, manufacture, testing, and maintenance of power connectors. It also includes the inspection and certification of power connectors to ensure they meet the required standards. The system also includes the tracking and monitoring of power connector performance over time. The system should also include the development of corrective action plans to address any issues that arise.

5.Can 40 series power connectors be quickly and easily disconnected?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, power connectors can be quickly and easily disconnected. Many types of power connectors feature a quick-release mechanism that allows them to be disconnected with minimal effort.

6.Can 40 series power connectors support high-frequency signals?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can support high-frequency signals. However, the type of connector used will depend on the specific application and the frequency of the signal. For example, coaxial connectors are often used for high-frequency signals, while screw terminals are better suited for lower-frequency signals.

7.About 40 series power connector production capacity

The production capacity of power connectors depends on the type of connector and the manufacturer. Generally, the production capacity of power connectors is determined by the number of machines and the number of workers available. The production capacity of a single machine is usually limited to a few thousand pieces per day. However, with the help of automation, the production capacity of a single machine can be increased to several hundred thousand pieces per day.

8.How do you choose the right 40 series power connector for a specific application?

We have established a good reputation and reliable partnerships within the 40 series power connector industry. 1. Consider the current and voltage requirements of the application. 2. Determine the type of power connector that is compatible with the application. 3. Consider the environmental conditions in which the power connector will be used. 4. Consider the size and shape of the power connector. 5. Consider the cost of the power connector. 6. Consider the availability of the power connector. 7. Consider the safety features of the power connector.

9.Can 40 series power connectors be used in automotive or marine applications?

Our company has many years of 40 series power connector experience and expertise. Yes, power connectors can be used in automotive and marine applications. However, it is important to ensure that the connectors are rated for the specific application and environment.

10.Can 40 series power connectors be used for both AC and DC power?

We have established a good reputation and reliable partnerships within the 40 series power connector industry. No, power connectors are designed to be used for either AC or DC power, but not both.

11.Can 40 series power connectors be used for high-power applications?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can be used for high-power applications. However, it is important to select the right type of connector for the application, as some connectors are not designed to handle high power levels.

12.Are there any special tools or techniques required for installing a 40 series power connector?

Our 40 series power connector products undergo strict quality control to ensure customer satisfaction. Yes, special tools and techniques are required for installing a power connector. Depending on the type of power connector, you may need a crimping tool, soldering iron, wire strippers, and/or heat shrink tubing. Additionally, you may need to use specific techniques such as soldering, crimping, and/or heat shrinking to ensure a secure connection.

13.About 40 series power connector origin

The origin of power connectors can be traced back to the early days of electricity. In the late 19th century, the first electrical connectors were developed to connect electrical devices to power sources. These connectors were made of metal and were designed to be inserted into a socket. Over time, the design of power connectors has evolved to include a variety of shapes and sizes to accommodate different types of electrical devices. Today, power connectors are used in a wide range of applications, from consumer electronics to industrial machinery.

14.What is the difference between a straight and a right-angle 40 series power connector?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. A straight power connector is a type of connector that has two straight sides that are parallel to each other. This type of connector is typically used to connect two devices that are close together. A right-angle power connector is a type of connector that has two sides that are perpendicular to each other. This type of connector is typically used to connect two devices that are farther apart.

Tag:4 pin power connector round,4 pin computer power connector,rtx 3070 power connector