feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

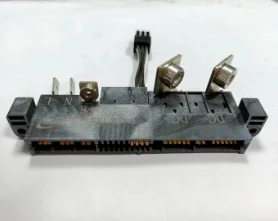

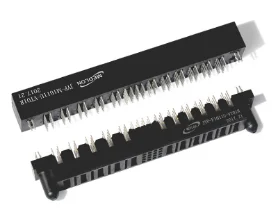

| Type: | 4 pin to 8 pin power connector | Packaging Details: | carton |

| Application: | Electric equipment | Supply Ability: | 9184 Piece/Pieces per Week |

| Place of Origin: | Chian,shenzhen | Port: | shenzhen |

| Brand Name: | Medlon | Quantity (pieces): | > 954 |

| Model Number: | Customized options | Lead time (days): | To be negotiated |

| Contact barrel wire size: | 4-14AWG 13.3-3.3m㎡ | Feature: | makes assembly quick and easy |

| AVG contact resistance: | <132 | system: | Flat wiping contact system |

| Contact material: | Silver plated copper | Color: | Colored modular housings |

| Voltage rating: | 658V | Application: | Electric vehicles;Medical equipment;Power supply;Electric equipment |

| Rated current: | 43A | MOQ: | 30 |

1.What kind of material is commonly used for making 4 pin to 8 pin power connectors?

We focus on innovation and continuous improvement to maintain a competitive advantage. Power connectors are typically made from metals such as copper, aluminum, and brass, as well as plastics such as nylon and polycarbonate.

2.Can 4 pin to 8 pin power connectors handle high voltages?

Being one of the top 4 pin to 8 pin power connector manufacturers in China, We attach great importance to this detail. No, power connectors are not designed to handle high voltages. High voltage applications require specialized connectors that are designed to safely handle the high voltage.

3.About 4 pin to 8 pin power connector raw materials

Power connector raw materials are typically made from metals such as copper, aluminum, and brass. These metals are chosen for their electrical conductivity, strength, and corrosion resistance. Plastics such as polycarbonate, nylon, and ABS are also used in the construction of power connectors. These materials are chosen for their durability, flexibility, and insulation properties.

4.How do you prevent the pins on a 4 pin to 8 pin power connector from getting damaged?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Inspect the pins for any damage before connecting the power connector. 2. Make sure the pins are aligned correctly before connecting the power connector. 3. Use a connector with a locking mechanism to ensure the pins stay in place. 4. Use a connector with a dust cover to protect the pins from dirt and debris. 5. Use a connector with a strain relief to reduce the stress on the pins. 6. Use a connector with a flexible cable to reduce the strain on the pins. 7. Use a connector with a protective sleeve to reduce the risk of pin damage. 8. Use a connector with a protective cap to reduce the risk of pin damage. 9. Use a connector with a protective shield to reduce the risk of pin damage. 10. Handle the connector with care to avoid any accidental damage to the pins.

5.About 4 pin to 8 pin power connector inventory

Power connector inventory is a type of inventory that is used to track the various types of power connectors that are used in a variety of electronic devices. This type of inventory is important for ensuring that the right type of power connector is available for any given device. It also helps to ensure that the correct type of power connector is used in the correct application. This type of inventory can be used to track the quantity of each type of power connector, as well as the type of connector and the manufacturer.

6.About 4 pin to 8 pin power connector quality system

A power connector quality system is a set of processes and procedures that are used to ensure the quality of power connectors. This system includes the design, manufacture, testing, and maintenance of power connectors. It also includes the inspection and certification of power connectors to ensure they meet the required standards. The system also includes the tracking and monitoring of power connector performance over time. The system should also include the development of corrective action plans to address any issues that arise.

7.Can 4 pin to 8 pin power connectors be used for high-power applications?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, power connectors can be used for high-power applications. However, it is important to select the right type of connector for the application, as some connectors are not designed to handle high power levels.

8.How does the operating temperature range affect the performance of a 4 pin to 8 pin power connector?

The operating temperature range of a power connector affects its performance in several ways. Higher temperatures can cause the connector to become brittle and more prone to cracking or breaking. Higher temperatures can also cause the connector to expand, which can lead to poor contact between the connector and the mating part. Lower temperatures can cause the connector to become stiff and difficult to insert or remove. Additionally, lower temperatures can cause the connector to become brittle and more prone to cracking or breaking.

9.How do you ensure proper polarity when using a 4 pin to 8 pin power connector?

We continuously upgrade our skills and knowledge to adapt to changing 4 pin to 8 pin power connector market needs. 1. Check the polarity markings on the connector and the power source. 2. Make sure the positive and negative terminals are connected correctly. 3. Use the correct type of connector for the power source. 4. Use a multimeter to test the polarity of the connection. 5. Use a polarized connector to ensure proper polarity.

10.About 4 pin to 8 pin power connector delivery date

The delivery date for power connectors will depend on the type of connector, the quantity, and the supplier. Generally, most suppliers will provide an estimated delivery date when the order is placed. If the order is urgent, some suppliers may be able to provide a faster delivery time.

11.Are there any color code standards for different 4 pin to 8 pin power connectors?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, there are color code standards for different power connectors. The most common color code standards are the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). The IEC color code standard is used for most European countries, while the NEMA color code standard is used in the United States.

12.Does the size and configuration of a 4 pin to 8 pin power connector affect its performance?

We are a professional 4 pin to 8 pin power connector company dedicated to providing high quality products and services. Yes, the size and configuration of a power connector can affect its performance. The size of the connector determines the amount of current it can handle, and the configuration of the connector affects the amount of power it can deliver. For example, a larger connector can handle more current than a smaller one, and a connector with more pins can deliver more power than one with fewer pins.

13.Are there any options for tool-less installation of 4 pin to 8 pin power connectors?

Yes, there are several options for tool-less installation of power connectors. These include push-in connectors, twist-lock connectors, and snap-in connectors. Push-in connectors are the most common type of tool-less power connector and are designed to be inserted into a power socket without the need for any tools. Twist-lock connectors are also available and are designed to be twisted into place. Finally, snap-in connectors are designed to be snapped into place without the need for any tools.

Tag:six pin power connector,motherboard main power connector,breakaway power connector