feature: Input voltage: maximum 220V, minimum 110V Output voltage: generally 5V or 12V Input current: Varies according to output voltage and load power Output power: depends on load capacity and output voltage Working frequency: generally 50Hz or 60Hz Advantage: 1. Versatility: Combination AC-DC and split power options are available, and the module can be configured to fit most designs 2. Convenient and flexible: easy to maintain and replace. 3. Safe and reliable: waterproof, dustproof and durable, 4. Quick connection: plug-in connection, can be quickly connected and disconnected, convenient for daily use 5. Multiple interface options: such as circular connectors, square connectors, threaded connectors, etc.

Specifications

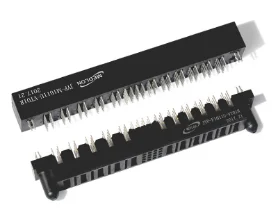

| Component Type | 1660 super power connector |

| Gender | Header/Receptacle |

| Header Pin Pattern (Left to Right) | Power/Signal |

| Number of Contacts (Power) | 4 |

| Number of Rows (Power) | 1 |

| Number of Contacts (Signal) | $keyworrd{12} |

| Number of Rows (Signal) | 7 |

| Termination Style | Solder To Board |

| Orientation | Right Angle |

| Pitch (Power) | 6.35mm (0.250in) |

| Pitch Signal) | 2.54mm (0.100in) |

| Current Rating | $keyworrd{13}A max. for One Powered Contact |

| Resistance (Power Contact) | Maximum for mated pair is 2mΩ |

| Resistance (Signal Contact) | Maximum for mated pair is 20mΩ |

| Dielectric Withstanding Voltage | $keyworrd{14}V DC for power ; $keyworrd{15}V DC for signal contacts |

| Durability (Mating cycles) | $keyworrd{16} Mating Cycles |

| Operating Temperature Range | -$keyworrd{13}°C to +125°C |

| Material Housing | PPA, glass fiber reinforce, UL94V-0 |

| Plating Contact area | 0.76μm (29.921μin) Gold |

| ail Plating (Signal) | 1.98μm (78μin) Tin |

| Tail Plating (Power) | 1.98μm (78μin) Tin |

| Guide Feature | Guide Pin Pocket |

| Packaging | Cartons or Tray |

1.Are there any specific considerations when using 1660 super power connectors for industrial applications?

As one of the 1660 super power connector market leaders, we are known for innovation and reliability. Yes, there are several considerations when using power connectors for industrial applications. These include: 1. Ensuring the connectors are rated for the voltage and current requirements of the application. 2. Ensuring the connectors are rated for the environmental conditions of the application. 3. Ensuring the connectors are compatible with the mating connectors used in the application. 4. Ensuring the connectors are designed to meet the safety requirements of the application. 5. Ensuring the connectors are designed to meet the durability requirements of the application. 6. Ensuring the connectors are designed to meet the EMI/RFI requirements of the application.

2.How do you ensure proper polarity when using a 1660 super power connector?

We continuously upgrade our skills and knowledge to adapt to changing 1660 super power connector market needs. 1. Check the polarity markings on the connector and the power source. 2. Make sure the positive and negative terminals are connected correctly. 3. Use the correct type of connector for the power source. 4. Use a multimeter to test the polarity of the connection. 5. Use a polarized connector to ensure proper polarity.

3.Can 1660 super power connectors be used in harsh environments?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, power connectors can be used in harsh environments. Many power connectors are designed to be durable and resistant to extreme temperatures, dust, moisture, and other environmental factors.

4.Are there any environmentally-friendly options for 1660 super power connectors?

Our company has many years of 1660 super power connector experience and expertise. Yes, there are several environmentally-friendly options for power connectors. These include connectors made from recycled materials, connectors with low-impact manufacturing processes, and connectors with low-emission designs. Additionally, some connectors are designed to be more energy efficient, reducing the amount of energy used during operation.

5.About 1660 super power connector patent

A power connector patent is a type of patent that covers the design and/or function of a power connector. This type of patent is typically used to protect the design of a power connector from being copied or used without permission. It can also be used to protect the function of a power connector, such as the way it connects to a power source or the way it transmits power. Power connector patents can be used to protect a wide range of products, from small electronic devices to large industrial machines.

6.How does impedance affect the performance of a 1660 super power connector?

As one of the 1660 super power connector market leaders, we are known for innovation and reliability. Impedance affects the performance of a power connector by limiting the amount of current that can flow through the connector. If the impedance is too high, the connector will not be able to handle the amount of current needed to power the device. If the impedance is too low, the connector will be overloaded and may cause damage to the device.

7.About 1660 super power connector payment method

Power connector payment method is a payment system that allows customers to pay for goods and services using their mobile phones. It is a secure and convenient way to make payments, as customers can use their phones to make payments without having to enter their credit card information. The system is also designed to be fast and easy to use, allowing customers to make payments quickly and securely. Power connector payment method is becoming increasingly popular as more businesses are beginning to accept it as a payment option.

8.Do 1660 super power connectors have a maximum number of mating cycles?

As one of the top 1660 super power connector manufacturers in China, we take this very seriously. Yes, power connectors typically have a maximum number of mating cycles. This number can vary depending on the type of connector and the manufacturer, but is typically between 500 and 1000 cycles.

9.About 1660 super power connector warranty

Power connector warranties vary depending on the manufacturer. Generally, power connectors are covered by a limited warranty that covers defects in materials and workmanship for a specified period of time. The warranty period may range from one year to five years, depending on the manufacturer. Some manufacturers may also offer extended warranties for their power connectors. It is important to read the warranty information carefully before purchasing a power connector to ensure that it is covered by the warranty.

10.About the scale of 1660 super power connector factory

The scale of a power connector factory depends on the size of the market it serves and the type of products it produces. For example, a factory that produces high-end power connectors for the aerospace industry may require a larger scale of production than a factory that produces basic power connectors for consumer electronics. The size of the factory may also depend on the number of employees and the amount of equipment and machinery needed to produce the connectors.

11.Can 1660 super power connectors be used for both AC and DC power?

We have established a good reputation and reliable partnerships within the 1660 super power connector industry. No, power connectors are designed to be used for either AC or DC power, but not both.

12.What is the expected lifespan of a 1660 super power connector?

We continuously upgrade our skills and knowledge to adapt to changing 1660 super power connector market needs. The expected lifespan of a power connector depends on the type of connector and the environment in which it is used. Generally, power connectors are designed to last for many years, but in some cases, they may need to be replaced after a few years of use.

13.About 1660 super power connector raw material procurement system

The Power Connector Raw Material Procurement System is a software solution designed to streamline the procurement process for power connector raw materials. It provides a centralized platform for suppliers to submit bids, and for buyers to compare and select the best option. The system also includes features such as automated order tracking, inventory management, and supplier performance tracking. This system helps to reduce costs, improve efficiency, and ensure that the best quality materials are purchased.

14.How do you select the appropriate locking mechanism for a 1660 super power connector?

1. Consider the application: The type of locking mechanism you choose should be based on the application and the environment in which the power connector will be used. For example, if the connector will be used in a harsh environment, you may want to choose a locking mechanism that is more robust and resistant to corrosion. 2. Consider the size: The size of the power connector should also be taken into account when selecting a locking mechanism. If the connector is too small, then a locking mechanism that is too large may not fit. 3. Consider the cost: The cost of the locking mechanism should also be taken into account when selecting the appropriate locking mechanism for a power connector. If the cost is too high, then it may not be feasible to use the locking mechanism. 4. Consider the safety: The safety of the power connector should also be taken into account when selecting the appropriate locking mechanism. If the locking mechanism is not secure enough, then it could lead to accidental disconnection of the power connector.

15.What is the typical insertion and extraction force for a 1660 super power connector?

We continuously upgrade our skills and knowledge to adapt to changing 1660 super power connector market needs. The typical insertion and extraction force for a power connector will vary depending on the type of connector and the application. Generally, the insertion force should be between 0.5 and 2.5 pounds, while the extraction force should be between 0.5 and 5 pounds.

Tag:atx 12v power connector pinout,6 pin power connector to 8 pin,pc board power connector,rtx 3080 power connector,c5 power connector